How Lithium Battery Chargers Work: DIY Tips, CC-CV Basics & Safety Guide

Table of Contents

- What Is A Lithium Battery Charger?

- Do You Have To Use A Lithium Battery Charger To Charge Lithium Ion Batteries?

- Do You Need A Special Charger For Lithium Batteries?

- How Can I Make My Own Lithium Battery Charger?

- Do Lithium Battery Chargers Have Overcharge Protection?

- Can You Use A Lithium Battery Charger To Charge Two Batteries In Series?

- Conclusion

Today nearly everything from electric vehicles to portable power stations relies on a lithium battery charger. At its core, a lithium charger isn’t much more than a power supply engineered to hold current steady as it feeds your cells, seamlessly shifting voltages to keep the charge flowing just right. Yet behind that simple definition lies a carefully orchestrated dance between AC transformation, DC conversion, and precise CC‑CV control—ensuring your pack fills safely, efficiently, and without overrun.

In this article, we will take a look at exactly how lithium battery chargers work, why their constant‑current/constant‑voltage profile is non‑negotiable for lithium chemistries, and even how you can build your own lithium battery charger.

What Is A Lithium Battery Charger?

A lithium battery charger is essentially just a constant current power supply. A constant current power supply regulates current by changing the output voltage to whatever it needs to be to maintain the set level of current.

Internally, a lithium battery charger consists of 2 main components- The AC side and the DC side. High voltage AC comes in and is transformed down to some intermediary voltage that is then rectified and filtered before being sent to a DC to DC converter. The DC side of a lithium battery charger is responsible for regulating current by dynamically adjusting its output voltage.

Do You Have To Use A Lithium Battery Charger To Charge Lithium Ion Batteries?

You don’t have to use an off‑the‑shelf lithium‑ion charger—you can build your own with a DC‑to‑DC converter. However, any charger (whether DIY or commercial) must still comply with the same charging rules: it needs to regulate both current and voltage precisely, following the CC‑CV (constant current–constant voltage) profile that lithium‑ion cells require. In essence, if your DC‑to‑DC converter is configured correctly to manage current and voltage limits, it is a lithium‑ion battery charger.

There are also some special cases where a lead‑acid charger can work for certain lithium‑ion chemistries. You definitely cannot use a lead‑acid charger for NMC (nickel manganese cobalt) cells, the most common lithium‑ion chemistry, because their voltage range doesn’t match. However, with LFP (lithium iron phosphate) cells—which have a lower nominal voltage and lower maximum voltage—you can arrange four LFP cell groups in series to reach a 12 V pack. At that point, the pack’s voltage range nearly aligns with that of a standard 12 V lead‑acid battery, making a lead‑acid charger usable for charging LFP packs as long as the charger is current-limited.

So, while you don’t strictly have to buy a lithium battery charger, whatever charging solution you use must adhere to the same fundamental requirements.

Do You Need A Special Charger For Lithium Batteries?

If by ‘special’ you mean able to regulate current and have an output range that covers the voltage range of the battery you are trying to charge, then yes, you need a special charger for lithium ion batteries.

The things that make a lithium battery charger special are its ability to regulate current for the first charging phase, and then regulate current for the second charging phase. Don’t let the phases confuse you, because every bench power supply and constant current regulator does this automatically.

All it means is that once that battery reaches the target charge voltage, the regulator will no longer regulate current, and the current will naturally fall off while the cell voltage remains constant. That's literally how a lithium battery charger works.

How Can I Make My Own Lithium Battery Charger?

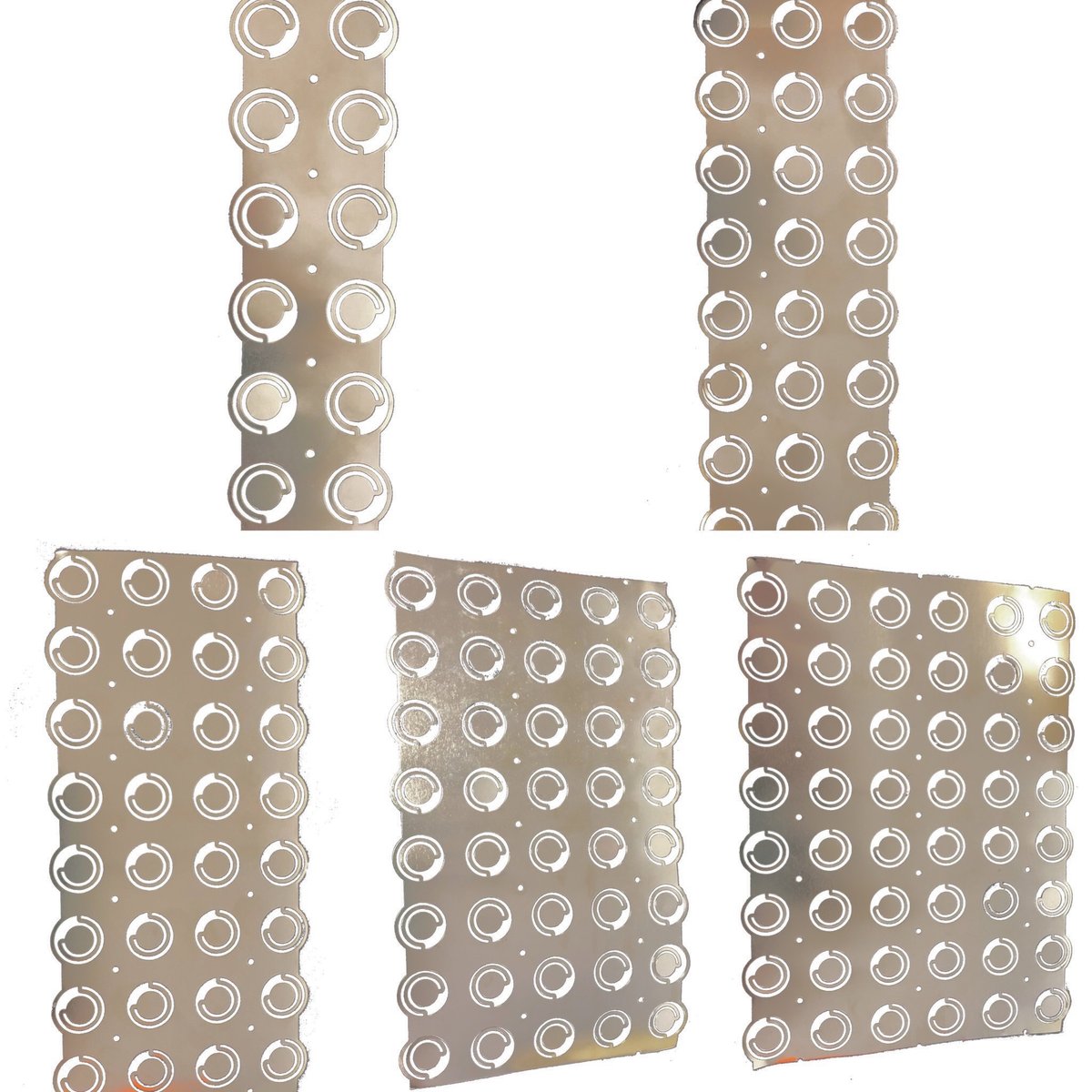

Absolutely! Check out this standard lithium battery charger. It has a max charge voltage of 54.6V and a current limit of 2A. That means its designed for a 13S NMC Lithium ion battery.

It's not difficult to make a charger that will work for any battery that the charger above will work for. In this case, all you would need would be a 24V DC power supply and this constant current boost converter. Simply plug the

Simply attach the output of the power supply to the input of the boost converter. After that, set the output voltage and output voltage to 54.6 and the current to somewhere between 1 and 10 amps depending on the battery you are interested in charging.

Do Lithium Battery Chargers Have Overcharge Protection?

Not really, and I’ll explain why. Most batteries are bulk‑charged, meaning they do not have a balance connector—you only have the main positive and main negative connections. So that’s all the charger can “see” on most lithium‑ion batteries.

Yes, the lithium battery charger is not going to go over 54.6 volts—that’s the highest it’s set to and can go. It can’t magically go higher than that. You might think this means it could never overcharge a cell. Well, what if you have 13 cell groups and 12 of them are at 3.5 volts while one is at 2 volts? The lithium battery charger will push current until the pack voltage reaches 54.6 volts total. It doesn’t care that one cell is at 6 volts and another at 2 volts (or one at 20 volts and another at 1 volt)—it simply can’t see individual cells.

A BMS would detect that imbalance and disconnect charging, but that protection comes from the BMS, not the charger itself. In contrast, a balanced charger—which, in general, is much rarer because it requires access to each cell group via an external connector—is common in the RC world (airplanes, drones, etc.). That kind of lithium battery charger is able to monitor each cell group and provide true overcharge protection.

Bulk chargers, which constitute roughly 90 % of all lithium‑ion battery chargers, lack this feature because they have no way to monitor individual cell groups. That’s one of the many reasons we rely on a BMS to handle overcharge protection.

Can You Use A Lithium Battery Charger To Charge Two Batteries In Series?

Yes but you shouldn't for the same reason you shouldn't discharge two lithium ion batteries in series. The MOSFETs inside a lithium battery BMS are rated for a particular voltage level. While they are on, they have a very low resistance, so the voltage across the MOSFET is very close to zero. But the moment the MOSFETs in one of the BMS turn off (such as when the BMS disconnects charging or discharging) the MOSFETs in the deactivated BMS will see the full voltage of the circuit. This almost always results in damaging the BMS and sometimes results in a fire.

At least in the case of discharging batteries in series, you can use them safely until one of them dies. So, in that situation, you just have to monitor the state of charge of the lowest capacity battery, which is arguably much easier to do than manually preventing a battery from reaching full charge.

Conclusion

Lithium battery chargers come in a variety of power levels and form factors and can range from absolutely no settings to full control over the current and voltage limits. At the end of the day, a lithium battery charger is a device that can supply a constant current charge phase followed by a constant voltage charge phase while regulating voltage and current to within set parameters.

We hope this article helped you learn everything you needed to know about lithium battery chargers, thanks for reading!