How To Choose A BMS For Lithium Batteries

Table of Contents

If you are looking to build safe-high performance battery packs, then you are going to need to know how to choose a BMS for lithium batteries. The primary job of a BMS is to prevent overloading the battery cells. So, for this to be effective, the maximum rating on the BMS should be greater than the maximum amperage rating of the battery.

When choosing a BMS for a lithium-ion battery, the most important aspect to consider is the maximum current rating of the BMS. In addition to that, you need to make sure the BMS supports the correct number of series cell groups. Also, wireless connectivity is important to you, make sure the BMS you are looking to buy has Bluetooth because most BMSs do not. A BMS’s discharge current, charge current and balance current.

In this article, we will go over all of the various aspects of a BMS. We will explain what they do and why they are important. After that, we will tell you how to find the best BMS for your application.

How To Choose A BMS For Lithium Batteries

In order to choose the best BMS for your lithium battery, you will need to know a little bit about the functions that a BMS provides.

[[ aff type=cta ~ bg=`` ~ main=`Guided BMS Picker` ~ second=`Need help picking a BMS, use the tool found at the link below to get guided to the correct BMS. ` ~ btnText=`BMS Picker` ~ btnLink=`https://cellsaviors.com/bms-picker` ~ align=`center` ]]

Overcurrent Protection

Detection circuitry inside the BMS continuously monitors the current flowing through the BMS discharge MOSFETs. If this current rises above a certain threshold, the BMS switches off the MOSFETs and effectively removes the battery pack's electrical connection to the outside world.

Undervoltage Protection

The BMS will monitor the cell voltage of each cell group and if any of them go lower than a certain threshold (usually around 2.6 volts), the BMS is disconnected so that the battery cells don’t get damaged.

Overvoltage Protection

When charging a lithium-ion battery, a high voltage is applied across many sets of lithium-ion cells in series. If any one of the cell groups reaches the maximum charge voltage of a lithium-ion battery (4.2 volts), then the charge MOSFETs will be switched off to prevent overcharging the battery cells.

Cell Balancing

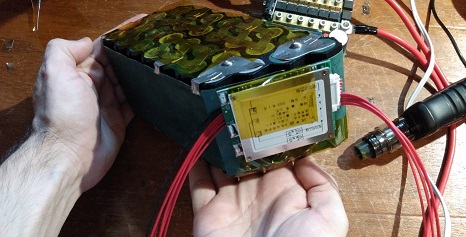

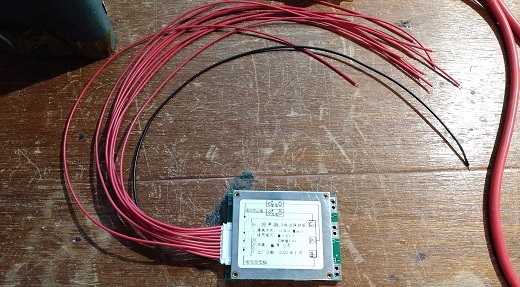

The difference between each cell group is monitored in the BMS. The cell group is detected to have a slightly higher voltage than the other cell groups, a small balance current is applied to the cell group. Over time, the high cell group’s voltage is brought down to the other cell groups. Balancing is handled by several small wires which go from the BMS to each cell group.

Connectivity Features

Higher-end BMS modules will either include a built-in Bluetooth interface or a generic UART interface that a Bluetooth module can be attached to. In some cases, you can even hook a USB cable up to your computer and manage your BMS from your PC.

Temperature Monitoring

Monitoring the temperature of the battery pack is an important but optional component of a BMS. In most cases, a properly designed system with a functioning BMS won't ever get hot enough to need to monitor the temperature.

Lithium-iron-based batteries, however, can be damaged if they are changed while being below a certain temperature. So, temperature monitoring is much more common for those types of cells.

Do Lithium Batteries Needs A BMS

Lithium-ion batteries do not require a BMS to operate. With that being said, a lithium-ion battery pack should never be used without a BMS. The BMS is what prevents your battery cells from being drained or charged too much. Another important role of the BMS is to provide overcurrent protection to prevent fires.

BMS modules are not expensive (compared to the rest of the battery pack) and they are relatively easy to install. So, there is really no reason to not use a BMS. There are a few super special and rare situations where it may make sense to not use a BMS, but they are outside of the scope of this article.

How To Know What Size Of BMS To Get

When someone refers to the ‘size’ of a BMS, they are generally referring to the maximum amount of current the BMS can handle. You need to make sure to get a BMS that can support the amount of power that is required by your load.

In fact, it's a good practice to add about 15% more current carrying capacity just so you have a little bit of headroom. After all, you don't want to run your BMS (or anything else, for that matter) at its absolute maximum ratings.

Let's say you have a 1000W inverter that you want to be able to safely run at max load. In this example, we will consider a 7S lithium-ion battery running a 24-volt AC inverter. A 7S lithium-ion battery has a fully charged voltage of 29.4 volts and a dead voltage of about 18.5 volts.

Drawing a 1100W load from the battery pack will require around 37 amps when the battery is fully charged.

1100 watts ÷ 29.4 volts = 37.4 Amps

At first glance, it may seem like you just need a 45 amp BMS. After all, your peak current will only be 37.4 amps, and adding an extra 15% to that comes to just 43 amps.

But wait.

When the battery is nearly dead, the voltage will be much lower. So, what happens when the amount of watts that you need stays the same but the voltage goes down?

The current goes up.

1100 watts ÷ 18.5 volts = 59.5 Amps

As you can see, you have to plan for the maximum amount of current that your battery will have to provide at its lowest voltage. So, in this example, you would want a 70 amp BMS.

What Happens If You Build A Lithium Ion Battery Pack Without A BMS

Lithium-ion battery packs are composed of many lithium-ion cells in a complex series and parallel arrangement. Many cells are needed when building a battery pack in order to provide the right amount of voltage, capacity, temperature, and current-carrying capacity characteristics.

The ways in which lithium-ion cells have to be arranged inside a battery pack depends on the cells and connections to the cells being exactly the same. In the real world, however, this is never the case. Even if cells are the same brand and type, and even if they are from the same production run in the factory, no two are the same. Also, no two spot welds and no two solder joints are the same.

So, because of this, there needs to be some active circuitry living inside the battery pack that monitors its internal state so corrections to natural imbalances can be made. The BMS actively monitors each cell group's voltage and provides a balanced current to compensate.

The BMS shuts things down when they get out of spec. If anything unusual happens, a BMS will do what it can to resolve the problem. If it cannot, it will effectively put the BMS into sleep mode which shuts the battery pack off. Building a battery without a BMS is dangerous and can result in fires, injury, and loss of life.

What Does 100amp BMS Mean?

When a BMS is spoken of in terms of amps, that’s generally in regards to its sustained current carrying capacity. So, a 100 amp BMS will be capable of supplying at least 100 amps of current continuously. The rating is a significant amount less than a BMS’s burst or peak capability. Generally speaking, a BMS that can do 100A continuously can do up to 150 to 200 amps for a short amount of time.

What’s The Best BMS For 18650 Cells?

Well, that is actually a rather broad question with no single answer. When it comes to picking the best BMS, the brand is not super important. Choosing the perfect BMS for a small to medium size project really comes down to down to the specific application.

If you are building a small USB battery bank, then you might only need a 10 to 20-amp 3S BMS. If, however, you are building a power wall battery, you would need a 6S or 7S BMS that can handle at least 50 amps of current for most applications.

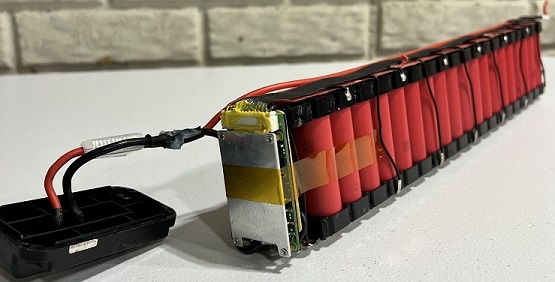

What’s The Best BMS For Ebike Battery

Ebikes take lithium-ion batteries and BMS modules to the next level. Space requirements are tighter, current requirements are higher, and the highest possible capacity is desired. This means that it’s important for the cells and BMS in an e-bike battery to be top-notch hardware.

This is when brands start to matter.

For the overwhelming majority of applications, JBD is the best BMS for e-bikes. JBD BMS modules have an extremely high build quality and are fully sealed devices. This means they are water and mature-proof. A JBD BMS will always be able to provide its rated amount of current and they are known to be among the most reliable eBike BMS on the market.

How To Choose A BMS For Lithium Batteries - Conclusion

Building lithium-ion battery packs come with a lot of responsibility. That is why it's so important to know how to choose a BMS for lithium batteries. Even though a BMS is not required for a battery to function, they are required for a lithium-ion battery to be safe.

If you want to choose the right BMS, you need to consider things like the maximum current rating of the BMS, and it’s very important to ensure that it supports the correct output voltage range for your application. It’s also important to make sure the BMS you are wanting to buy has the right discharge current, charge current, and connectivity features that fit your particular use case.

We hope this article helped you learn more about how to choose a BMS for lithium batteries. Thanks for reading!