How To Pick Best Cells For A Battery Pack

Table of Contents

Are you wanting to learn how to build the perfect battery? There is a lot to consider when learning how to pick the best cells for battery projects.

While it is true that batteries come in many different sizes, shapes, voltages, and chemistries, lithium-ion batteries are by far the most common type of battery cell that you will come into contact with. It is important to consider, however, that not all lithium-ion cells are the same. In fact, lithium-ion cells within the same sub-chemistry can have substantially different properties.

In this article, we will go over all of the factors that need to be considered when picking battery cells for your project.

Factors To Consider While Choosing A Battery

Let's take a look at each battery cell parameter in order to gain a better understanding of battery performance and operation.

Availability Of Space

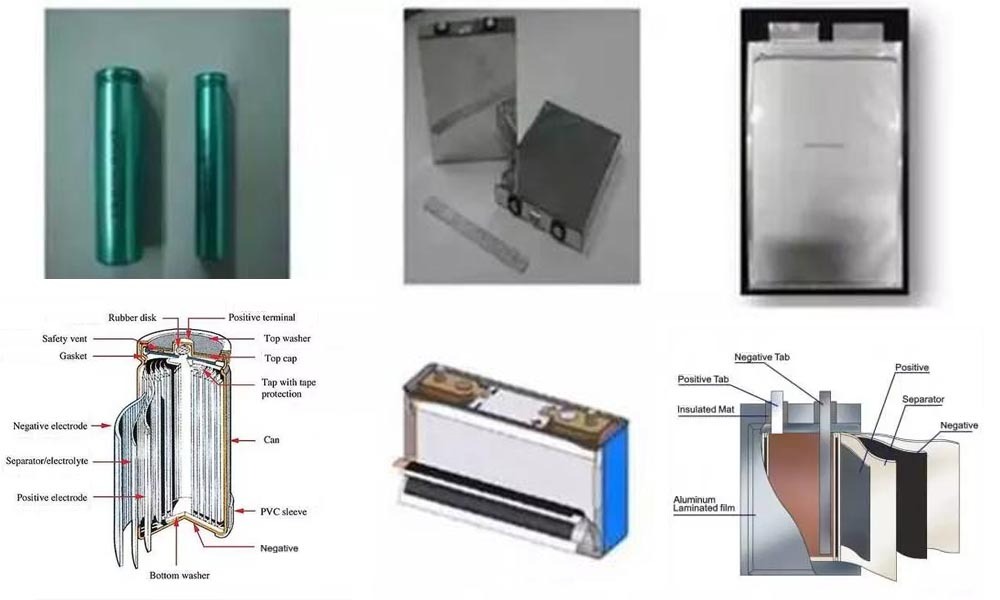

Lithium Ion battery cells come in all kinds of shapes and sizes. There are thin, skinny ones, short fat ones, big tall ones, and just about everything else in between. Regardless of what type of lithium-ion cell you come across, however, they will filter down into 3 categories. Canisters, Pouch, and Prismatic.

Canister/Cylindrical Cells

Canister cells also known as cylindrical cells are by far the most common type of lithium-ion battery cells. Like anything else packaged in a cylinder, canister cells can be manufactured extremely quickly. This makes them the least expensive to produce and that is why they are most common. They are safer to use than pouch cells because they have a hard steel shell.

When To Use Canister/Cylindrical Cells

Canister cells are the most common and most available type of battery. So, as long as you have a spot welder, you really should be using canister cells. Their low cost and size along with their relatively high energy and packing densities make them a viable solution for most applications.

Pouch Cells

Pouch Cells, also known as lithium polymer cells, are the ones you find in modern, sleek laptops, phones, and some other thin gadgets. They generally have a higher current-carrying capacity than canister cells due to the larger contact surface area of the cathode and anode. The problem with lipo cells is that they have no hard casing. This means if you physically impact a pouch cell, you are in for quite a situation.

When To Use Pouch Cells

Because of their lack of any sort of protective layer and their high cost, it's best to use pouch cells only if you absolutely have to. These types of batteries swell under normal operation and if this is not taken into consideration, it can cause an explosion.

Prismatic Cells

Prismatic cells are an attempt at the best of both worlds. They are basically massive lipo cells that are built into a hard metal casing. They are still complicated to manufacture because they are not round and cannot roll through any sort of machine easily. So, they are generally more expensive.

When To Use Prismatic Cells

Prismatics are reliable and have a high energy density. The drawback here is that they are rather large cells. So, if you are making something like a power wall or other static, non-moveable battery, prismatic cells can be a good solution.

One of the most common is 18650 vs 21700 Cells

Cylindrical or Prismatic Cells

In addition to looking at cell format, we have a guide that covers the best cell chemistry for your build.

Lithium NMC vs Lithium LFP (LifePO4)

Operating Voltage

Battery voltage is pretty much the most important characteristic of a battery. Battery voltage is determined by the internal structure and chemistry of the battery. While it may seem like a dead battery will have a voltage of 0V, this is not the case. In fact, if a battery is reading as 0V, that means it is damaged.

Standard cobalt-based battery cells have a running nominal voltage of about 3.7 volts. In contrast, iron-based lithium battery cells have a running voltage of around 3.25 volts. So, if you are using lithium iron (LiFePO4) batteries, you will have to put more in series.

Operating Temperature

This is an extremely important and often overlooked one. Most people will consider how important it is to make sure your batteries don't exceed a certain temperature due to their operation, but the ambient operating temperature is often overlooked. Performance, reliability, and even safety can be diminished if a battery pack is operated outside its temperature scope. At first glance, one may reasonably assume that there is only an upper-temperature threshold, but there is also a lower-temperature threshold.

It's best to charge lithium-ion batteries between 20°C to 45°C. Outside of this range, you will not be able to safely charge a lithium-ion battery at its rated current. If you do, it will result in lower battery cycle life. If you need to charge lithium-ion batteries in temperatures ranging between 5°C and 10°C, you will have to slow the charge down to a crawl in order to prevent dendrite plating on the electrolyte.

Capacity Of The Battery - Amp Hours & Watt Hours

If a given battery cell has a nominal voltage of 3.7 volts and a capacity of 3.5 amp hours, that means it can store 12.95 watt-hours of energy. The formula to derive watt hours is extremely simple. All you have to do is multiply the nominal voltage by the capacity and it will tell you the watt-hours.

If a battery has a nominal voltage of 3.7 volts and a 2 Ah (amp hour) capacity, that means it can store 9.4 Wh (watt hours) of energy. This means that the battery could power a .94W load for 10 hours or a 9.4W load for 1 hour. It also means that it can power an 18.8W load for 30 minutes.

In another example, a battery pack that has a nominal voltage of 36 volts and a capacity of 15 Ah will be able to store 540 Wh (watt hours) of energy. This means that the battery could power a 540W load for 1 hour or a 54W load for 10 hours, and so on.

Batteries that have a higher capacity do not always provide faster discharge capability. This fact is important to consider.

Cost Of Battery Cells

Generally speaking, the battery is the most expensive single part of any system. In most cases, many battery cells are required to achieve optical characteristics. For this reason, cost becomes a huge factor in choosing the best type of battery for your project.

Which Battery Should I Choose?

When it comes down to how to pick the best battery cells for your project, it's important to make sure the cells can support the currents your application demands. Remember, the current is shared between the cells in parallel and not shared between the cells in series. This means if you have a battery pack that is made with 10 cell groups in series and 3 cells in parallel in each group, whatever your load current is will be divided by 3 across the cells in the P group.

So, if you are running a 30-amp load on a 10S3P battery pack, each cell in the battery pack will be under a 10-amp load.

Conclusion

There are many factors to take into consideration when learning how to pick the best cells for battery projects.

It’s important to remember that canister cells are the hardest to work with but they are the most available and generally the lowest cost. Pouch cells are a bit dangerous and kind of expensive so you should only use them when you absolutely have to. Prismatics are heavy, large, and can be somewhat expensive. They are, however, the easiest to work with as they all have screw terminals on them.

We hope this article helped you learn how to pick the best cells for your project. Thanks for reading!