Lithium Pouch Or Cylindrical Cells

Table of Contents

- What Is A Cylindrical Battery

- What Are Pouch Cells

- Is A Lipo Cell the Same as Lithium-Ion?

- What Are The Advantages And Disadvantages Of Cylindrical Cells

- What Are The Advantages And Disadvantages Of Pouch Cell

- Differences Between Pouch And Cylindrical Cells

- Is The Packing Efficiency Of Pouch Cells Higher Than Cylindrical Cells

- How Do Pouch Cells Connect

- Are Pouch Cells Or Cylindrical Cells Better For Powerwall?

Pouch cells and cylindrical are both lithium-ion batteries. These two battery formats have a lot in common but there are also some key differences. Cylindrical cells can be one of several chemistries while pouch cells are typically NMC.

Pouch cells come in all kinds of shapes and sizes. This makes them ideal for small, portable electronics. This is in contrast to cylindrical cells which are only available in a few sizes. Pouch cells can run higher discharge currents than cylindrical cells, but they also don’t have the hard, protective casing that cylindrical cells. Choosing to use pouch or cylindrical cells really depends on your application. Generally speaking, it's best to use cylindrical cells until it's not viable to do so. If cylindrical cells cannot meet your project's needs, then consider using a pouch cell.

In this article, we will compare and contrast pouch and cylinder lithium-ion battery cells. We will also go over some of the advantages and disadvantages of each battery format.

What Is A Cylindrical Battery

A cylindrical battery is unsurprisingly a battery in the shape of a cylinder. Cylindrical batteries have a strong, metal case that encloses the anodes, cathodes, and separators. The cylinder shape makes this type of cell low-cost to manufacture while providing a great deal of strength. The most common cylindrical cell sizes are 18mm x 65mm and 21mm x 70mm also known as 18650 and 21700 cells.

What Are Pouch Cells

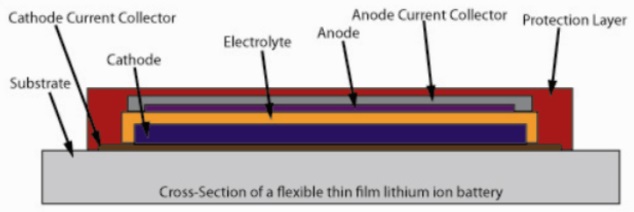

Pouch cells are a lithium-ion battery that has the cell chemistry contained in an aluminum foil pouch. Inside a pouch cell, the positive and negative sides are separated with a polymer film. This type of cell has no metal casing, so they are lighter than canister cells. Pouch cells are widely used in portable, small electronic devices.

Is A Lipo Cell the Same as Lithium-Ion?

Yes. Often in conversation and on social media posts, you will see people make a distinction between the two. For example, someone will say, “I’ve been using lipos on my ebike but I’m planning on switching to lithium-ion.”

The reality is that pouch cells, also commonly referred to as lipo cells are a subset of lithium-ion battery technology. So, a lipo cell is a lithium-ion cell, but in a pouch instead of a metal canister.

What Are The Advantages And Disadvantages Of Cylindrical Cells

Cylindrical cells are low cost and their insides are relatively safe due to the metal outer casing. Cylindrical cells are used in e-bike batteries, electric cars, and off-grid batteries. You can also find cylindrical cells in flashlights, remote controls, power tools, medical devices, drones, and much more.

Advantages

● Low cost is the main advantage of cylindrical cells

● Cylindrical cell production is reliable, consistent, and fast.

● High-temperature resistance

● High strength

Disadvantages

● Lower energy density due to gaps between cells

● The steel casing makes them heavier

● Lower discharge current.

What Are The Advantages And Disadvantages Of Pouch Cell

Pouch cells definitely have their place in society. They can often produce far higher currents than canister cells and they can be made to fit odd spaces more easily and are more energy dense.

Advantages

● The polymer separator and aluminum foil casing makes them light

● Pouch cells can deliver more current than a cylindrical cell of the same size

● Lower internal resistance

● Can be made in many sizes and shapes

● Higher energy density

Disadvantages

● Complicated to manufacture

● Easy to puncture

● Under heavy use they swell a lot

● Under normal use they swell somewhat

Differences Between Pouch And Cylindrical Cells

Pouch cells can deliver more current and can be made to fit just about any shape or size. Cylindrical cells, on the other hand, are strong and have good heat dissipation characteristics.

Pouch cells will expand over the life of the battery pack whereas cylindrical cells stay the same size. The phenomenon plays a key role in properly designing a system to use pouch cells. When you are using pouch cells much more care has to be taken in terms of where the battery will go and the room inside that cavity.

Cylindrical cells, on the other hand, always stay the same size. This is because they have a hard metal case and are designed in such a way that they do not expand under normal operation. Personally, I feel like this is the key attribute that makes cylindrical cells the better option in most cases.

Is The Packing Efficiency Of Pouch Cells Higher Than Cylindrical Cells

Yes. Pouch cells have a higher internal energy density and can be packed very efficiently. Cylinder cells have a packing efficiency of about 90 percent. This is in contrast to pouch cells that can have packing efficiencies as high as 99 percent. So in a given space with a cylindrical cell, you will have about 9% dead space compared to pouch cells.

No matter how much effort you put in, you won’t be able to fill all of the space with cylindrical cells because they have a circular footprint. Circle packing is a highly complicated science and it can get really overwhelming, really quick, but I will tell you this: The hexagonal pattern is the most efficient packing format you can use for cylindrical cells.

How Do Pouch Cells Connect

Connections are made to pouch cells through the terminal tabs that extend through the seals. These tabs can be used to either make connections with the other pouch cells or to the load. Simply solder the connections together and make sure they are properly insulated from other connections. Some do choose to spot-weld these connections together.

When it comes to pouch cells vs cylinder cells, this is a major win for pouch cells. Unlike pouch cells, cylindrical cells are not easy to make an electrical connection to. To connect to cylindrical cells (and therefore to connect cylindrical cells together to form battery packs) requires special equipment and experience.

Are Pouch Cells Or Cylindrical Cells Better For Powerwall?

Generally speaking, cylindrical cells will be the best for power walls. More often than not, a powerwall battery does not need to be as small as possible. Also, powerwall batteries are relatively large, especially when you build a DIY powerwall. This means you will have to buy a lot of cells to make one and cylinder cells are way cheaper.

Conclusion

When choosing between pouch cells or cylindrical cells for your project, it can be a tough decision. Once you know each type of battery’s strengths and weaknesses it makes the process a lot easier

Pouch cells are easier for manufacturers to produce in odd sizes across a large range of sizes. This is why pouch cells are used for small, portable electronics. Cylindrical cells, on the other hand, are only available in a few sizes. The fact that they are in metal cans of just a few sizes, however, makes them much cheaper to produce. Pouch cells do have the benefit of being able to run more current than cylindrical cells, but they also totally lack any of the armor that cylindrical cells have. Choosing to use pouch or cylindrical cells depends on the application, but it's generally best to use cylindrical cells unless there's some requirement for the project that makes them no longer viable (such as weight or size).