How Do You Calculate Which BMS for LiFePO4?

Table of Contents

You can calculate the BMS (Battery Management System) for Lithium Iron Phosphate (LiFePO4 or LFP) batteries by dividing the nominal voltage that your project needs by 3.25, which is the nominal voltage of LiFePO4 chemistry, and rounding to the nearest whole number.

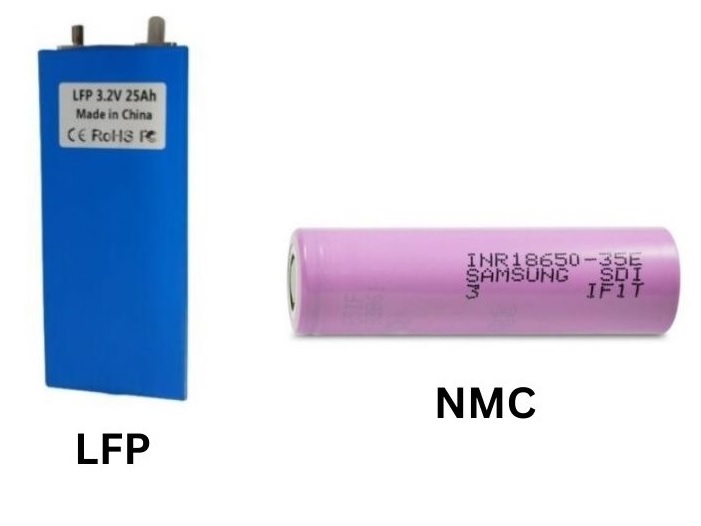

NMC vs LifePO4 Voltages

LiFePO4 chemistry has a full charge voltage of around 3.7 volts, a nominal voltage of 3.25 volts, and a dead voltage of about 2.5 volts. NMC (Nickel Manganese Cobalt) battery chemistry that you would usually find in 18650 and 21700 cells, has a full charge voltage of 4.2 volts, a nominal voltage of 3.7 volts, and a dead voltage of around 2.5 volts.

This means that to achieve the same overall nominal battery voltage, more LFP cells would need to be used in series. In either case, it’s the nominal voltage that you need to calculate the number of series connections, and therefore, know which BMS to use.

Calculating BMS for Different Voltages

To illustrate, let's calculate the BMS for a 48-volt LiFePO4 battery. Dividing 48 by 3.25, we get 14.76. Then, we round this to the nearest whole number, which would be 15. This means that the battery requires 15 cell groups in series to achieve a 48-volt nominal voltage. You can see that we had to round, so let’s see what the actual figures for the battery will be.

Dead Voltage:

15 Cells in Series x 2.5 volts nominal = 37.5V

Nominal Voltage:

15 Cells in Series x 3.25 volts nominal = 48.75V

Fully Charged Voltage:

15 Cells in Series x 3.7 volts nominal = 55.5V

For a 72-volt battery, we divide 72 by 3.25, which gives 22.15. Rounding down, we have 22S. If you multiply this number by the nominal voltage (3.25), you achieve a nominal voltage of 71.5 volts, quite near the intended 72 volts.

Dead Voltage:

22 Cells in Series x 2.5 volts nominal = 55V

Nominal Voltage:

22 Cells in Series x 3.25 volts nominal = 71.5V

Fully Charged Voltage:

22 Cells in Series x 3.7 volts nominal = 81.4V

Additional BMS Features

There is much more to a BMS than the number of cells in series that it supports. Things like temperature protection, remote monitoring, over-current protection, and series support also matter. These are especially important for LFP chemistry, as it cannot be charged below-freezing temperatures. Charging under freezing can lead to rapid cell damage, this can be overcome by keeping the cells warm in cold conditions.

Does The Number of Parallel Cells Matter When Calculating LiFePO4 BMS?

No. The number of cells in parallel doesn't matter. Most BMS are hard-wired to handle a specific amount of series groups. The number of cells in parallel doesn't need to be taken into consideration because adding more cells in parallel doesn't add more series connections. Remember, when adding cells in parallel, only the amps are added. To add voltage, and therefore add more series connections, more cells need to be put in series.

The Importance of Smart LiFePO4 BMS

For large batteries with more than around 14 cells in series, a smart BMS becomes highly recommended, provided your budget and available space can accommodate it. It works in the other direction as well. For instance, if your battery configuration involves a significant number of cell groups in parallel—say, more than 10 or 15— then the same thing applies.

These smart BMS systems are more expensive and are physically larger than their non-smart counterparts, but for setups with a lot of cells, remote monitoring becomes more of a requirement than an option.

[[ aff type=cta ~ bg=`` ~ main=`Guided BMS Picker` ~ second=`Need help picking a Smart BMS, use the tool found at the link below to get guided to the correct LiFePO4 BMS. ` ~ btnText=`BMS Picker` ~ btnLink=`https://cellsaviors.com/bms-picker` ~ align=`center` ]]

How To Calculate LiFePO4 BMS Amperage

Calculating the amperage for the BMS involves understanding the load your project will demand from the battery and the capacity of your cells. In general, the BMS should be able to handle at least the maximum current your project will draw. It is crucial to take the time to make sure you choose the right BMS for your project, picking wrong can lead to inefficiencies and possibly dangerous working conditions.

To calculate the amperage for the BMS, first, determine your project's maximum current draw. This information can often be found in the specifications for the device or system you're powering. If your system requires, for instance, 30A, you need a BMS that can handle at least 30A.

It’s important for the BMS to be able to handle potential surge currents - the brief moments when your device might draw more power than usual. A good rule of thumb is to choose a BMS that can handle 1.5 to 2 times the maximum continuous discharge rate of your battery.

Selecting a LiFePO4 BMS with a Higher Amperage Rating

If you're uncertain about your system's exact current draw, or if it may vary significantly, it's safer to choose a BMS with a higher amperage rating. Remember, the amp rating on a BMS is a measure of how much power it can handle, not a measure of how much power it will put out. A BMS with a higher amperage rating than your system requires will still function effectively and can provide an additional layer of protection against unexpected power surges.

Note that the BMS must not only be able to handle the maximum current that your project will draw but also the maximum charging current. This becomes more important if you're using a fast charger or if your charger's current exceeds the BMS's current rating. If the BMS cannot handle the charging current, it may cause the BMS to malfunction, which can in turn damage the battery or even become a fire hazard.