Cell Level Fusing for Lithium Batteries

Table of Contents

Cell level fusing is a safety measure for lithium-ion batteries that provides a physical barrier to prevent overcharging and overheating.

Cell-level fusing works by installing a fuse at the cell level, which will automatically cut off power to the battery if it exceeds a certain temperature or voltage. This helps to prevent dangerous situations such as explosions or fires caused by overheating or overcharging. The main benefit of doing cell-level fusing is that it improves the reliability and safety of lithium-ion batteries. Cell level fusing prevents a dramatic over-current situation which can lead to overheating and thermal runaway. Cell level fusing somewhat helps to prolong a battery's overall lifespan by essentially removing bad cells. I say ‘somewhat’ because once a cell is removed there will be an imbalance in the P group which will inevitably lead to an imbalance in the S groups, which reduces the overall battery lifespan. It’s important to consider, however, that this reduced lifespan is still much longer than if the bad cell had not been removed from the circuit.

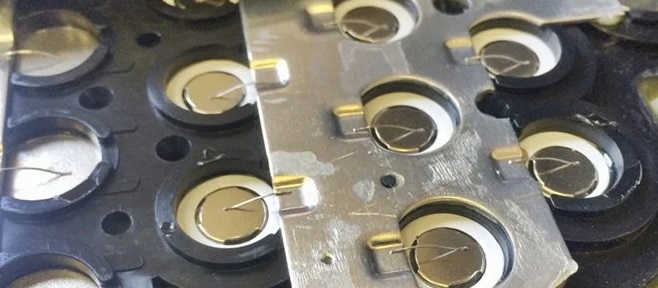

For the longest time, wire bonding was the most viable option for cost-effective implementation of cell-level fusing. It’s a process that uses ultra-thin wires that function as a fuse to connect the battery cells to a bus bar. This method is relatively inexpensive but it can be rather difficult to implement. Luckily, there is a much more intuitive and economical solution, which is Batty Hookup cell-level fuse sheets. These nickel sheets are specially manufactured so that every cell point is fused. This is achieved by cutting a specific shape into the nickel where the cell is usually welded. Using these sheets makes it so that you can build a lithium-ion battery in a totally traditional way and it will just automatically be fused.

In this article, we will cover the basics of cell-level fusing, why it's so beneficial, and what some of its current limitations are.

What Is Cell Level Fusing?

Cell level fusing is a technology that uses a fuse to connect each individual cell of a lithium-ion battery together to prevent overcharging, over-discharging, and overheating. This ensures that if one cell becomes damaged, it will be much less likely to cause a chain reaction that could lead to a fire or explosion.

Potential Applications For Cell-Level Fusing

Cell-level fusing technology has the potential to improve the safety and performance of lithium-ion batteries in a wide range of industries, including electric vehicles and energy storage systems. In electric vehicles, cell-level fusing is pretty much critical. You have to consider that there are literally thousands of cells in a car battery pack.

How Does Cell Level Fusing Compare To Other Battery Safety Mechanisms?

Cell level fusing is just one of many safety measures that can be used in lithium-ion batteries. Other measures include thermal management, which helps to keep the battery at a safe temperature, and overcharge protection, which prevents the battery from being charged too much. Cell level fusing is unique in that it provides a physical barrier to prevent an out-of-control cell from hurting the rest of the pack.

Another thing to consider is this: Let's say you have a non-fused battery pack and a cell goes haywire. There is a chance that the heat alone can move from one cell to another simply through convection. And remember things that carry electricity well generally carry heat well. A non-fused pack has an intentionally large, wide conductor connecting all the cells. In contrast, a fused pack has only a just enough conductor connecting the cells to the rest of the system.

This means if things do go badly for a given cell, the excess heat will not have the main, thermally conductive path to spread to other cells that a non-fused pack will.

What Happens If A Cell Goes Bad In A Battery That Features Cell Level Fusing?

If a cell goes bad in a battery that features cell-level fusing, the fuse associated with that cell will activate and open the circuit, preventing the damaged cell from further charging or discharging and preventing any potential chain reaction that could lead to a fire or explosion. This is basically the entire point of cell-level fusing.

Once the fuse is activated, the damaged cell is equal to having been physically removed from the pack. No joke. It's exactly the same as turning the battery off, breaking it down, taking out the bad cell, and putting the battery back together. All automatically. This, of course, will reduce the capacity of the battery pack, but not just in the obvious way. As previously mentioned, the new state of the battery with the bad cells removed will be an imbalanced battery.

To be totally honest, the best thing you can do if a cell goes bad and a fuse activates is to intentionally destroy the same number of fuses that burned out, but in every other cell group.

For instance, If you have a 5S15P battery and one of the cells in a P group goes bad and blows its fuse, it’s best to disable one of the cells in every other P group. This will turn the battery into what is effectively a 5S14P battery, but at least the battery pack will be in balance.

Challenges Of Cell Level Fusing

While cell-level fusing can be an effective safety measure for lithium-ion batteries, implementing it on a large scale can be challenging. One major challenge is that cell-level fusing requires a fuse to be placed in each individual cell of the battery, which can add complexity and cost to the manufacturing process. Additionally, the fuses themselves can add a small amount of resistance to the battery, which can slightly reduce its overall performance.

What Is An Easy Way To Implement Cell Level Fusing?

Historically, wire bonding was just about the only reasonable way that one could achieve cell-level fusing. This is a technique that involves using thin wires made of materials such as gold or aluminum to connect the individual cells within a battery.

To implement cell-level fusing with wire bonding, a fuse is connected in series with each cell using a specialized conductor and specialized machines. These fuse wires are designed to activate at a specific current or temperature threshold, providing an additional layer of safety to your project.

Overall, wire bonding is a viable option for implementing cell-level fusing in lithium-ion batteries, but it has a massive learning curve and again, requires specific, specialized equipment. It is, however, highly scalable. If you are feeling discouraged, fret no. There is a better way.

Fused Nickel Strip: The Easiest Way To Implement Cell-Level Fusing

If wire bonding sounds a bit overwhelming, fret not. Battery hookup makes a special nickel conductor that is specifically made for cell-level fusing. These specially cut nickel conductors make it extremely easy to add cell-level fusing to any lithium-ion battery project.

[[ aff type=aff ~ link=https://www.batteryhookup.com/discount/CS5?redirect=/collections/accessories/products/nickel-fuse-2p-wide-continuous-roll-by-the-foot-18650-cell-level-fusing ~ title=`Fused Nickel Strip` ~ image=https://admin.cellsaviors.com/storage/fused nickel strip.jpg ~ description=`Fuses blow at 8 amps and can carry 3 amps continuously. ` ~ height=small ~ buttonText=`5% Off Using This Link` ]]

These sheets from Battery Hookup take all the fuss out of cell-level fusing. They make it so that the lithium-ion construction process is no different than building a non-fused battery. They are low-cost, easy to use, and reliable. There are, however, some drawbacks.

They are only available in linear formats, so if you are dreaming up an easy-to-build, individually fused, highly compact, offset battery pack, you are out of luck for now.

Also, because the fuse links are built into the sheets, there is no way to change them. That means if the fuse threshold is too high or too low for your application, then these sheets won't work for you. For more information on what these sheets can handle, I suggest you visit the battery hookup website for the most updated information.

Cell Level Fusing Will Get Cheaper And Easier Over Time

As cell-level fusing technology continues to evolve, researchers are exploring new materials and designs that can improve the performance and safety of lithium-ion batteries. For example, some are experimenting with using new types of fuses made from materials that are more heat-resistant or that can withstand higher currents. Others are exploring new designs for the fuses themselves, such as using multiple fuses in parallel to provide additional protection.

The cost of cell-level fusing will likely come down as technology advances and more companies enter the market. Some key areas that will need to be developed include:

- Improved materials for fusing cells, such as more efficient and durable fuses

- Better methods for aligning and fusing cells, such as advanced imaging techniques

- Development of high-throughput techniques for fusing large numbers of cells at once

- Advancements in automation to reduce labor costs

Conclusion

Whether you are new to lithium-ion batteries or have been building them for years, the concept of cell-level fusing is generally relatively unexplored.

Cell-level fusing is a technique that helps improve the safety and reliability of lithium-ion batteries by installing a fuse at the cell level. This fuse automatically cuts off power if the battery exceeds a certain temperature or voltage, preventing potential dangers such as overheating, overcharging, and the possibility of explosions or fires.

In the past, wire bonding was a popular and cost-effective method for implementing cell-level fusing, but it can be challenging to implement. Today, there is a more efficient solution in the form of Batty Hookup cell-level fuse sheets. These nickel sheets are designed to fuse every cell point, making it easy to build a battery pack from 18650 cells with automatic fusing. The sheets are made by cutting specific shapes into the nickel where the cell is usually welded.

While cell-level fusing somewhat prolongs a battery's lifespan by removing bad cells, it also creates an imbalance in the battery's series and parallel groups, which can reduce the overall battery lifespan. However, this reduced lifespan is still much longer than if the bad cell had not been removed from the circuit. Also, the battery can be brought back into balance by strategically clipping other fuses to match everything back up again.

We hope this article had everything you needed to know about cell-level fusing, thanks for reading!!