Building A Lithium Battery Pack From 18650 Cells

Table of Contents

- How Are 18650 Cells Different From Other Batteries?

- Part and Tools Needed For Building A Battery Pack

- Where To Get 18650 Cells For A Battery Pack

- Determining 18650 Battery Pack Configuration and Number of Cells Needed

- 18650 Battery Pack Design

- Different Types of Cell Balancing

- How To Choose The Right Nickel Strip To Build a Battery

- Why Use 18650 Cell Holders

- Joining The 18650 Cells Together

- Steps for Building a Battery Pack with 18650 Cells

- Choosing A BMS and Its Importance

- How Many 18650 Batteries Make A 100Ah Battery?

- Conclusion

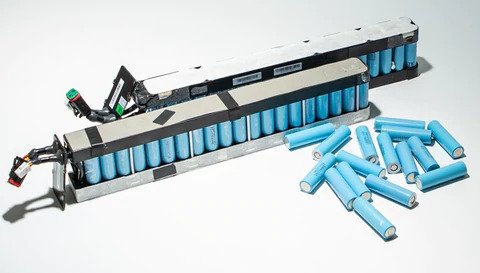

Lithium-ion is currently the best battery chemistry humanity has. It is the perfect choice when looking to build a battery pack with 18650 cells. In fact, 18650 cells are used in so many applications. It may not come as a surprise that you will find a lithium-ion battery in your laptop, in your drone, in your power tools, and even in your medical devices.

It's simply a matter of time before all the cars on the road are electric. Isn’t it fascinating to live in these times? All of us alive today will see the world make its major shift away from lumbering, fossil fuel-powered vehicles to a wider array of light electric vehicles that have far simpler and more efficient powertrains.

The most common type of lithium-ion battery cell by far is the 18650. Like all cylindrical battery cells, this one gets its name from having an 18mm diameter and 65mm height. So, as you would expect, a 18650 cell looks like a slightly larger AA battery.

For these reasons, there are a lot of people wondering how to build a battery pack from 18650 cells. In this article, we will teach you everything you need to know about how to build a DIY lithium battery pack from 18650 cells.

[[ ad ]]

How Are 18650 Cells Different From Other Batteries?

While a lithium-ion cell may be only slightly larger than a AA, an 18650 is vastly more powerful than any AA ever could be. There are several key differences between these types of battery cells.

For starters, 18650 cells have a higher voltage than AA cells. This means that it takes less 18650 cells in series to produce a voltage suitable for consumer electronics. Also, 18650 cells have far lower ISR (internal series resistance) than a AA battery. This makes it so less 18650 cells are required to achieve a given current carrying capacity.

If you are looking into other cell formats for your build we have put together a guide on picking the best cell type for your DIY battery build.

Another great thing about 18650 lithium-ion cells is their power density. While a typical AA battery contains only about 3.9 watt-hours of energy, a 18650 lithium-ion cell can store 13 watt-hours or more. This is no surprise, as energy density figures for modern lithium-ion cells are between 100 and 265 watt-hours per kilogram. Their energy density and power density make them an excellent choice for building a battery pack.

Part and Tools Needed For Building A Battery Pack

Battery Parts & Supplies

1. 18650 or 21700 Cells

[[ aff type=aff ~ link=https://www.batteryhookup.com/discount/CS5 ~ title=`18650 or 21700 Cells` ~ image=https://admin.cellsaviors.com/storage/30q_1024x1024@2x.jpg ~ description=`Battery Hook Up offers new and used cells for sale at amazing prices!` ~ height=small ~ buttonText=`5% Off Right Now` ]]

2. 18650 Cell Holders

3. BMS

[[ aff type=cta ~ bg=`` ~ main=`Guided BMS Picker` ~ second=`Need help picking a BMS, use the tool found at the link below to get guided to the correct BMS. ` ~ btnText=`BMS Picker` ~ btnLink=`https://cellsaviors.com/bms-picker` ~ align=`center` ]]

4. Nickel Strips

5. Charge & Discharge Connectors

6. PVC Heat Shrink

Battery Buildings Tools Needed

Whether you are building a battery pack with a soldering iron or using a spot welder, you are going to need a soldering iron. While we do cover how to build a battery pack from 18650 cells using spot welding vs soldering methods, we strongly recommend going the spot-welding route.

This is because when spot-welding a pack, soldering is not used to connect the cells together electrically. Instead, a soldering iron is only needed to make auxiliary connections and to make the connectors.

1. Spot Welder

[[ aff type=aff ~ link=https://amzn.to/3Xn7IWM ~ title=`Spot Welder` ~ image=https://admin.cellsaviors.com/storage/al3eM8KWcvsL2N5JGglTfBemnf8Tck-metac3BvdC13ZWxkZXIuanBn-.jpg ~ description=`Compact, lightweight, and portable spot welder. Easy to use, with stable performance.` ~ height=small ]]

2. Wire Stripper / Cutter

[[ aff type=aff ~ link=https://amzn.to/3GeBWCu ~ title=`Dowell Wire Stripper / Cutter` ~ image=https://admin.cellsaviors.com/storage/po4VIUgfVDXdHhzTYtfmIhhK16NPSo-metaZG93ZWxsLXdpcmUtc3RyaXBwZXIuanBn-.jpg ~ description=`Ergonomically designed wire stripper. Ideal for copper & aluminum wire from 10-22 AWG.` ~ height=small ]]

3. Heat Gun

[[ aff type=aff ~ link=https://amzn.to/3zIYqZU ~ title=`Prulde Heat Gun` ~ image=https://admin.cellsaviors.com/storage/pruldeheatgun.jpg ~ description=`Ultra sturdy, safe, and durable heat gun. Can be set at 752F or 1112F.` ~ height=small ~ buttonText=`Check price` ]]

4. Multimeter

[[ aff type=aff ~ link=https://amzn.to/3zK7v4B ~ title=`Digital Multimeter` ~ image=https://admin.cellsaviors.com/storage/multimeter.jpg ~ description=`Versatile backlit multimeter capable of measuring voltage, capacitance, frequency, resistance. ` ~ height=small ~ buttonText=`Check price` ]]

5. Lithium Ion Charger/Capacity Tester

[[ aff type=aff ~ link=https://amzn.to/3Fe5mPZ ~ title=`Charger & Capacity Tester` ~ image=https://admin.cellsaviors.com/storage/capacity-tester.jpg ~ description=`Safe & compliant universal battery charger. Works on plenty of formats of cells.` ~ height=small ~ buttonText=`Check price` ]]

6. Electrical Gloves

[[ aff type=aff ~ link=https://amzn.to/3qbrkyu ~ title=`Safety Gloves` ~ image=https://admin.cellsaviors.com/storage/rubberized safety gloves.jpg ~ description=`Twelve pack of rubber gripped safety gloves. ` ~ height=small ~ buttonText=`Check price` ]]

7. Kapton Tape

8. Barley Paper

[[ aff type=aff ~ link=https://amzn.to/3zHmHiZ ~ title=`Barley Paper` ~ image=https://admin.cellsaviors.com/storage/barley-paper.jpg ~ description=`Adhesive backed barley paper. Continuous length roll. Lightweight and easy to handle.` ~ height=small ~ buttonText=`Check price` ]]

9. Insulator Rings

[[ aff type=aff ~ link=https://amzn.to/3f6yI8j ~ title=`Insulator Rings` ~ image=https://admin.cellsaviors.com/storage/insulator-rings.jpg ~ description=`200 count 18650 cell insulator rings. Pivotal in protecting against battery shorts. Easy to peel and paste!` ~ height=small ~ buttonText=`Check price` ]]

10. Soldering Iron

[[ aff type=aff ~ link=https://amzn.to/3nb9JVu ~ title=`100W Soldering Iron Kit` ~ image=https://admin.cellsaviors.com/storage/soldering-iron.jpg ~ description=`100W, pencil style soldering iron kit. Heats up fast and the handle stays cool. Accurate temperature control.` ~ height=small ~ buttonText=`Check price` ]]

11. Safety Glasses

[[ aff type=aff ~ link=https://amzn.to/3NKHBol ~ title=`Safety Glasses` ~ image=https://admin.cellsaviors.com/storage/61MspO6nQFL._AC_UX679_.jpg ~ description=`Lightweight and comfortable eye protection. ` ~ height=small ~ buttonText=`Check Price` ]]

[[ ad ]]

Where To Get 18650 Cells For A Battery Pack

Buying New 18650 Lithium Ion Cells:

There are all kinds of 18650 cells on the market ranging from $2 to $10, but which one should you buy? If you are in the market for new cells, I recommend the following brands 18650 cells from Panasonic, Samsung, Sanyo, LG, and Molicel.

These 18650 brands have good track records and you can trust their datasheets and ratings. Most of the time, 18650 cells from these brands will cost more, but they are a battery value for the money. This is because higher-end cells often have higher capacities and more current carrying capacity.

Salvaging Lithium Ion Cells:

Many devices use 18650 cells. You can find them in everything from discarded scooter battery packs to old laptop batteries. You can also find excellent 18650 cells in modem and medical battery packs.

If you don't feel like salvaging 18650 cells on your own, we always pick up salvaged (and new) cells from Battery Hookup. They have the fairest pricing on cells, and everything that we have picked up so far has been high-quality. You can use discount code CS5 for 5% off your entire order at Battery Hookup.

[[ aff type=aff ~ link=https://batteryhookup.com/discount/cs5 ~ title=`New & Salvaged 18650 Cells` ~ image=https://admin.cellsaviors.com/storage/samsung-18650s.jpg ~ description=`Battery Hookup carries an assortment of high-quality new & salvaged 18650 cells at a fair price. Check out their selection of cells, they would be perfect for your next build!` ~ height=large ~ buttonText=`Shop 18650s` ]]

Determining 18650 Battery Pack Configuration and Number of Cells Needed

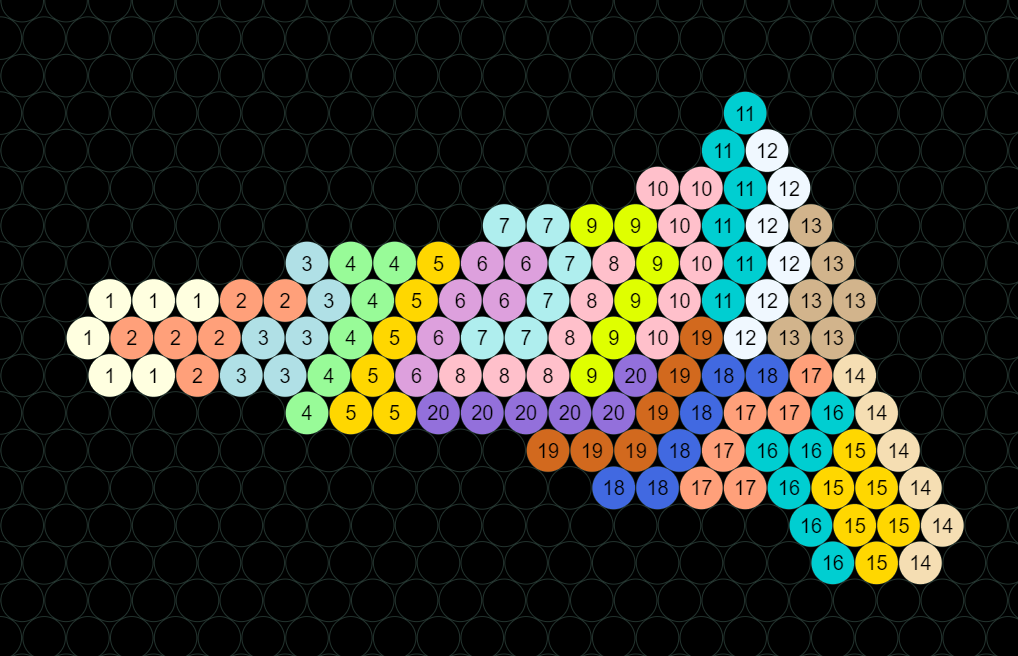

To make the battery pack you need, you must first know what voltage, amp hours, and current carrying capacity the battery needs to have. Connecting cells in series will increase the voltage while connecting cells in parallel increases their current-carrying capability. Any time you add cells, whether it's series or parallel, you gain capacity.

E-bike batteries typically run somewhere between 36 and 72 volts. Home Powerwall systems can be designed to run on 12, 24, and 48-volt systems, and just about anything in between. So, for this example, we will build a simple ‘24V’ battery using 2200mAh cells. I put the 24 in quotes because with lithium-ion cells, you can’t really build a perfect 24-volt battery.

The battery we build in this example will be used to power a 500W air conditioner through an inverter.

Determining Series Configuration

We have already determined that we need to run a 24-volt load. When building a 24-volt battery pack, it's best to use 7 cells in series. This is because lithium-ion cells have a depleted voltage of about 2.6 volts, a nominal voltage of 3.7 volts, and a fully charged voltage of 4.2 volts. So, that means 7 lithium-ion cells in series will have a nominal voltage of 25.9 volts, a fully charged voltage of 29.4 volts, and a dead voltage of around 20 volts.

As the battery dies, its voltage will fall into the low 20s, but this voltage range works fine with 24V inverters and other 24V appliances. So in this example, the battery will have a 7S configuration. If you're interested in reading more about how wiring lithium-ion cells into a series configuration works, check it out here.

Determining Parallel Configuration

In this example, the air conditioner is rated for 500W. So, that means it requires 500 watts per hour to run. It’s generally safe to assume that a decent 24V inverter is about 90 percent efficient. That means for the inverter to supply 500W of power, you would need to put at least 556W of power into it.

NOTE: This also means that to be able to power a device that uses 500W on the AC side of the circuit, you would need an inverter that is capable of more than 500W. Remember, the 500W limit is a limit on the overall power going through the inverter, rather than just a limit on the output.

It's important to not max out your equipment. So, if you need to draw 500W continuously, then you should go with an inverter that can provide no less than 750W.

Watts is volts times amps. So, if you have a nominal voltage of 25.9v, and you need to supply 556 Watts to a load, the load will draw about 21.5 amps from the battery pack. So, all you need to do is divide the 21.5 amps by the amount of Amps that an individual cell can provide to find out how many cells you need in your P groups.

NOTE: Each and every cell has its own figures, so for this example, we will assume that the 18650 cells can provide 5 amps of current. A quick calculation shows that a 7S battery would need 4.3 cells in its P groups to be able to run a window unit air conditioner. When doing this calculation, it's always best to round up. So, in this case, you would need a 7S5P configuration.

That means that to run a window unit air conditioner from a 24V inverter using 18650 cells that have a 5 amp CDR (Continuous Discharge Rating) and a 2200 mAh capacity, the absolute minimum is 7S5P configuration. Read more about configuring lithium-ion cells in parallel.

Online Tools For Building Lithium Ion Battery Packs

If all of this sounds confusing or maybe just a bit too much to keep up with, we highly recommend you check out the tools section. We have developed several tools that make building lithium-ion batteries easier.

Pack Planner tells you how long a given load will run on a particular battery and provides an estimation of the size battery that would be needed for a given application. Pack Builder helps you arrange cells in the most effective configuration based on each cell’s individual capacity. We also recently released our BMS Picker which will help you choose the right BMS for your build.

18650 Lithium Ion Cells To Avoid

Before you start your build you will need to pick what cells you are going to use. Steer clear of brands that offer impossible cells. As of this writing, the highest capacity 18650 cell is the Panasonic NCR18650G, which has a capacity of 3600mAh. So, if there is a company out there claiming to make something larger than a 3600ma 18650 battery cell, don't buy it.

In fact, it’s a good practice, in general, to avoid buying products from brands that are known to use inaccurate labeling.

There is nothing wrong with getting cheap cells or used cells. What you want to avoid, however, is buying cells that are marketed as new when they are used. Another thing you want to avoid is buying low-capacity cells that are marketed as having a much higher capacity.

So, it’s important to make sure the cells you are buying have been tested. The most reputable battery resellers have a policy of testing a selection of cells in each batch and usually post screenshots of the results.

Check The Cell Voltage

It is of critical importance to check the voltage of your cells before connecting them in parallel. Remember, if there is any voltage difference between the cells that you are connecting in parallel, energy will transfer from the higher voltage cell to the lower voltage cell as fast as it can. The difference in voltage is what determines the speed. So, the larger the voltage difference, the more the risk of a fire when you connect them.

While it's not dangerous to connect out-of-balance cells in series, it certainly can be inconvenient. This is because it takes quite a bit of time before most consumer BMS systems are able to bring cells within balance, and until it does, you won’t be getting anywhere near the full performance of your battery pack.

While it's still important to check your new cells, this is generally more of a problem when using used cells. As a general rule of thumb, you don't want to connect two cells together in parallel if they are any more than .1 volts off.

18650 Battery Pack Design

Determine the Load Current: The first step is to determine the load current, which is the amount of current required by the device that the battery pack will power. This is important because it determines the size of the wires and other components required to handle the current, as well as the number of cells needed to meet the required current.

Calculate the Capacity: Next, you need to determine the capacity of the battery pack, which is the amount of energy stored in the battery. You can calculate the capacity by multiplying the load current by the desired run time of the device.

Select the Cells: Once you have determined the load current and capacity, you can choose the cells that are capable of meeting these requirements. It's important to choose cells that have a high enough discharge rate to meet the load current and a high enough capacity to meet the desired run time.

Determine the Number of Cells: Based on the load current and capacity, you can determine the number of cells needed to meet the requirements. To calculate the number of cells, divide the desired capacity by the capacity of a single parallel group cell.

Different Types of Cell Balancing

There are various methods employed to keep cells balanced in lithium-ion battery packs. The most common way for most BMS systems to handle this is to essentially burn off excess energy in any cells that may have a slightly higher voltage than the others.

Depending on your application, you may want your battery back to either top-balance or bottom-balance your cells. In top balancing, the cells are brought into balance as the battery pack is being charged. This ensures that all cell groups have an equal voltage when the battery pack is fully charged.

In contrast, a bottom-balancing system will balance the cells as they discharge. This method ensures that all of the cell groups have equal voltages when the pack is dead.

How To Choose The Right Nickel Strip To Build a Battery

To make the battery pack, you will have to electrically connect the 18650 cells together. This is most commonly done using a spot welder and nickel strip. Avoid nickel-plated strips, and instead, opt for pure nickel strips. They cost a little more, but pure nickel strip has far lower electrical resistance.

When the electrical conductor used to join 18650 cells has a lower resistance, that means the battery pack will have less voltage drop under load. This leads to less heat generation during charging and discharging, which extends the battery’s life span while also ensuring that the battery maintains optimal performance throughout this extended life span.

Nickel strips are made in many different shapes and sizes for different cells and ways of building a battery pack. So, make sure to choose the right type of nickel strip based on your needs.

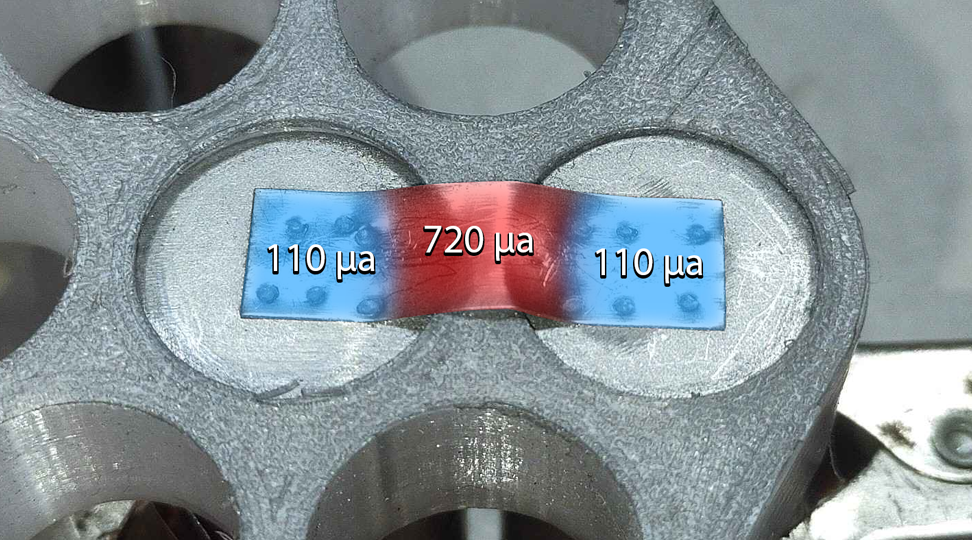

A high-quality pure nickel strip with a thickness of 0.015 inches is usually the standard for building a battery pack with 18650 cells. At this thickness, each millimeter of width can carry about 1 amp of current.

If you can’t afford an expensive spot welder, you can always pick up a lower-cost model. You would be surprised how effective entry-level spot welders are these days. If neither are an option for you, you can make a lithium-ion battery pack using a soldering iron and wire.

Why Use 18650 Cell Holders

Along with giving you an easy framework to build complete battery packs, using 18650 cell holders provide several advantages:

1. Cell holders provide critical spacing between the cells. This allows for much better-cooling characteristics as compared to cells that are in direct contact with each other. If the cells are touching each other and they undergo thermal runaway, it's much more likely the rest of the cells will also light up.

2. Using cell holders makes your battery pack more solid. If you don't use cell holders, you generally will have to rely solely on tape and glue to hold the battery pack together, and it more than likely must be as sturdy as it would have been if it was made with cell holders.

3. Cell holders give your battery pack an element of vibration resistance. If you are relying only on glue and tape to hold things together, then it's a lot easier to shake things apart.

For these reasons, we recommend always using 18650 cell holders when building a battery pack.

Joining The 18650 Cells Together

Place the first parallel group of cells positive side up. After that, place the second parallel group negative side up, and so on. The cell holders will have notches on the side that allow them to be interlocked.

Connect your cell holders together to form the needed shape of your battery with the needed amount of cell holes. After that, you can put your cells in. While it is possible to simply hot glue the cells together, using cell holders gives your battery pack better cooling characteristics among other benefits.

Option A: Spot Weld The Cells Together

Now it's time to connect the cells. Before welding, be sure to prepare the nickel strips.

The easiest way to do this is to lay your nickel strip on top of your parallel cells. Make sure that it covers all cell terminals. It's always good to leave around 10mm of strip hanging over the end for connecting the BMS sense wires. Remember, solid nickel strips with a thickness of 0.015 inches can carry about 1 amp of current per millimeter of width.

For series connections, simply cut small nickel strips to fit between your P groups. You will need to make sure that the nickel you are adding is enough to handle the current for your application. Generally speaking, each millimeter of width of 0.15mm nickel can carry about ¾ of an amp. If you need to carry higher current looking into how to spot-weld a copper-nickel sandwich will be the best way.

Start by connecting the negative terminal on the first parallel group to the positive terminal of the second group, and so on, all the way down.

Make sure there is no air gap between the welding electrodes and the nickel strip. Also, make sure there’s no air gap between the nickel strip and the battery terminal. When welding, you will see a tiny pair of sparks that will generate two small weld marks on the nickel strip.

As you are becoming acclimated to the welding process, it's good to make sure you have produced a quality weld by trying to pull off the nickel strip. So, it's good to practice spot-welding nickel onto a few cells before you do the build. If you've never spot-welded cells before we recommend reading our guide on how to spot-weld first.

If the nickel strips are difficult to remove, then chances are it's a good weld. If you can easily peel the nickel strip off, then you know you have a poor weld. If this happens, you may have to increase your welding current.

Option B: Solder The Cells Together

First of all I would just like to say that no one should be soldering lithium-ion batteries together. With that being said, the first step is to make sure to thoroughly clean the surface of your cells. After that, add flux to remove any oxidation that would prevent a quick, clean bond.

If you try to solder directly to a cell without using flux, while you may be successful, you certainly will have to press the soldering iron harder and hold it on the cells longer.

Use at least an 80W soldering iron. I know it may seem counterintuitive to recommend using a hotter soldering iron on battery cells. It’s important to consider, however, that the hotter the soldering iron, the less time you will have to spend with the soldering iron on the cell.

NOTE: If you hold your soldering iron on a cell for more than a short moment, you run the risk of damage to the battery.

Make sure to use a heavy gauge wire that can handle the amount of current your battery is going to need to provide. When soldering lithium cells together, make sure to not spend too much time in one place. As far as which connections to make, its the same as they would be if the pack was being welded.

Steps for Building a Battery Pack with 18650 Cells

[[ aff type=guide ]]

Step 1: Prepare your supplies and work area.

Clear your work area off and remove any metal pieces that may be laying on the bench or table that you are working on.

Install the insulator discs on the positive end of each cell. Also, test the voltage of each cell before connecting them together. This will ensure against any unexpected current flow when the cells are put in parallel.

Step 2: Weld the Cells Together

The first step in building your battery pack is to weld the 18650 cells together. This is done by connecting the cells together using nickel strips. It’s always best to use a spot welder rather than a soldering iron to make these connections because soldering simply puts too much heat into the cell.

You are going to have to make both parallel and series connections to build most battery packs. A parallel connection is made by connecting the positive terminal of one cell to the positive terminal of another cell, and similarly connecting the negative terminals. This increases the capacity and current-carrying capability of the battery pack, as the current can flow through multiple cells at once.

A series connection is made by connecting the positive terminal of one cell or cell group to the negative terminal of the next cell, and so on. This increases the voltage of the battery pack, as the voltage of each cell group in series is added together.

It is important to pay attention to the orientation of the cells when making these connections. If you connect them in the wrong order, you could damage the cells or even cause a fire. It’s also important to mask off areas as you go so that there are no exposed conductors that could lead to getting shocked or fire if a metal object is dropped on them.

Step 3: Connect the BMS

Once the cells are connected, you'll need to install the battery management system (BMS). The BMS is an important component that helps regulate the voltage and current within the battery pack. It also provides protection against overcharging and over-discharging.

Generally speaking, you want to connect the B- (usually blue) to the main battery negative. You want to connect the P- to the discharge negative (black). You want to connect the main battery positive to the discharge connector (red). There could be a C- connector if it's a separate port BMS, and if that is the case, a black wire would need to be run from there to the negative charge connection.

Just like the discharge connection, the charge connection positive is routed directly from the main battery positive to the charge connector (red).

After that is the BMS leads. There is no standard color for these but they generally have one red wire or one black one on one end to indicate either the most negative or most positive connection.

Take the most negative connection and connect it to the main battery negative. Moving up from there, connect each subsequent BMS lead to each subsequent cell group junction.

If you did it right, by the time you get to the other end you will have one wire left. Simply connect that final wire to the main battery positive and you are good to go.

If you are still unsure about connecting the balance lead check out our detailed guide on how to connect balance leads from a BMS.

If you do all that and you get no voltage on the output, don't freak out too hard yet. Most BMS require some sort of activation and that is generally done by placing it on a charger for like 0.1 seconds.

Life Hack:

On about 90 percent of BMS, you can get around the need to do this by shorting B- to P-. Doing that makes the battery think that it's getting a charge because although very tiny, the voltage difference before and after the MOSFETs is enough to trigger most BMS into thinking they are being charged.

No appreciable amount of current flows when doing this trick.

Step 4: Wrap the Pack

Once the BMS is connected, tape down any wires or exposed connections that you can see. After that, put barley paper (fish paper) on all sides of the battery. For the safest, most reliable battery, it should basically look like it's made out of paper. After you get it to that state, the next step is to wrap the battery pack in heat shrink tubing to help to protect the pack from damage and also provides insulation from moisture.

You can find the right size heat shrink by measuring the width and height of what you are trying to wrap, adding them together, and then adding 10%. So if you need to wrap a battery that is 100mm wide and 70mm tall, the formula goes like this:

100mm + 70mm = 170mm

170mm x 1.1 = 177mm

So this means that for this battery, you would need a heat shrink tubing that has a flat width as close to 177mm as possible.

Step 5: Test the Battery Pack

Before using the battery pack, it's important to test it to make sure it's working properly. You can do this by connecting a power source to the pack and measuring the voltage and current. If everything is working correctly, you're ready to use your DIY lithium-ion battery pack!

By following these steps, you should be able to build a lithium-ion battery pack using 18650 cells in no time. The process is simple and straightforward, and with the right materials and tools, you can have a high-quality battery pack in no time.

[[ aff type=guide ]]

Choosing A BMS and Its Importance

Once you have all of your parallel groups connected in series, you have a battery pack. The cell on one end of the chain will have a negative cell with nothing attached to it. That is your main battery negative. On the other end of the series chain, you will find a cell that has a positive end that nothing is connected to. That is your main battery positive.

While your 18650 battery is now technically ready to use, I wouldn’t recommend it. Remember, if you don’t have any form of over-current or over-charge protection, a battery can be dangerous. If something goes wrong with your battery, load, charger, or even a wire, you could be in for some serious trouble.

This is why a BMS is essential. A BMS, or Battery Management System, is a small circuit board that converts several dangerous, fairly useless lithium-ion cells into one safe, useful, battery pack. A BMS has several roles, and some more expensive BMS boards do more than others. Here are some of the most common functions that a BMS performs:

Overcharge Protection

A BMS Monitors the voltage of all cell groups. When any one of those cell groups reaches 4.2V, charging is stopped. This prevents your cells from being damaged from being overcharged, and also helps prevent fires.

Cell Balancing

If one or more of your cell groups are at a higher voltage than the others, a BMS uses a circuit and small balance resistors to lower the voltage of any high cells.

Over-Discharge Protection

A BMS disables the battery pack when any cell's voltage falls below a certain threshold. This threshold is usually 2.5 to 3.0 volts. Remember, if a cell goes much lower than that, it will get damaged.

Over-Current Protection

Another critical job of a BMS is to make sure the battery pack is not put under too much stress. So, every BMS has a maximum current that, if achieved, will turn the battery pack off. Over-current protection applies to both charging and discharging the battery pack.

Short Circuit Protection

A short circuit is equivalent to a 0 Ohm load. Ohm’s law states that the amount of current that will flow through a given circuit is a function of, among other things, the circuit’s resistance and voltage. When a short circuit condition is created, the only resistance to the flow of current will be the very low resistance of the conductor (wire or nickel) and cell itself. Check out our article on how to choose a BMS for your battery pack.

So, because a short-circuit condition creates an over-current condition, any BMS that has over-current protection also has short-circuit protection.

How Many 18650 Batteries Make A 100Ah Battery?

That depends on which cells you are using and what voltage you are trying to achieve. For example, if you are wanting to build a 12V battery and were using 2500mAh cells, you would do the math like this:

To build a battery using lithium-ion cells that is close to 12V without going too much over is going to be a 3S configuration. This is because lithium-ion cells have a nominal voltage of 3.7V.

So, 3 cells in series would give you a voltage of 11.1V. Remember, connecting cells in series adds their voltage but does not change their mAh. This 3S cell group on its own would have a voltage of 11.1V and a capacity of 2500mAh.

So, to find out how many 3S groups need to be put in parallel to get 100Ah, simply divide 100 by 2.5.

100 / 2.5 = 40P

So, to make a 100Ah battery in this case, you would need to put your cells in a 3S40P configuration.

3 x 40 = 120

You would need 120 2500mAh lithium-ion cells to make a 100Ah battery.

Conclusion

As you can see, there is quite a bit to consider when building a lithium-ion battery pack from 18650 cells. It can be quite difficult for a busy person to take the time to learn all of these terms when they really just want a battery. Before you build, make sure you check out our comprehensive guide on safety when working with lithium-ion cells.

We hope this article helped you build your very first lithium-ion battery pack from 18650 cells. Thanks for reading!