Pros and Cons of Soldering Vs Spot Welding Lithium Cells

Table of Contents

If you are new to building batteries or have not started building batteries just yet, then you may be wondering should I solder or spot welding lithium cells and which is best. Compared to soldering, spot welding will always be the easiest and most practical way to join lithium cells.

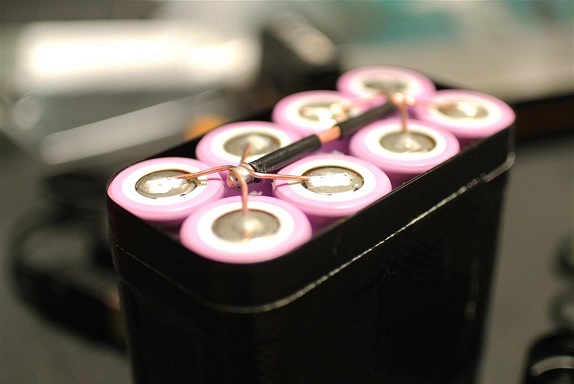

Spot welding lithium cells is easier to learn compared to soldering lithium cells due to the amount of soldering skill required to solder lithium cells properly. A soldered connection can easily have better electrical characteristics than a welded one, but it comes at the cost of damaging the cell while that extra electrical performance would have provided no real-world benefit.

A soldered connection is often more physically robust and stronger than a spot welded connection, but a spot welded connection is more than strong enough and again, the added strength of the soldered connection comes at the cost of lost capacity due to heat damage from the soldering process.

When it comes to soldering vs spot welding lithium cells, both types of connections are equally as reliable, but the soldering process can make the cells that the connections were soldered to less reliable. A spot welded battery will be at least an order of magnitude easier to build than a soldered lithium battery, and both are equally as difficult to repair due to the permanent nature of the two connections.

In this article, we will discuss soldering vs spot welding lithium cells. We will cover ease of construction, electrical connection quality, repairability, and more.

Learning Curve

It takes a high degree of skill to solder lithium cells. It’s not something that can easily be learned on the spot so that you can build a battery pack with 18650 cells. Soldering lithium cells requires a type of soldering that takes great skill to master.

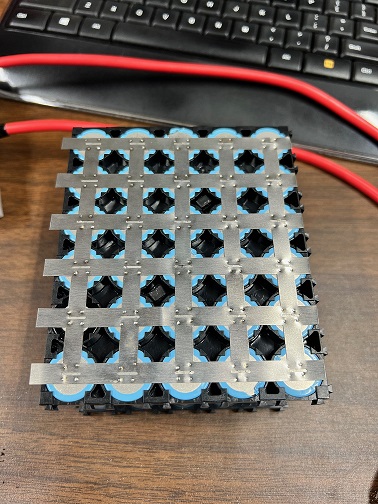

Spot welding, on the other hand, can be learned relatively quickly. It’s just a matter of adjusting the power of the welder to match what the material you are welding needs. After that, you just need to learn how much pressure to use when making the welds. This makes it so that when learning to spot weld, it only takes a few test cells that you can perform test welds on to be able to get it right. After that, you will be able to spot-weld a battery pack even if you have never welded before.

With soldering lithium cells, it’s a different story. Because of the fact that advanced soldering is required to solder lithium cells, it cannot easily be learned on the spot simply so that another task (building a battery) can be completed. High-power soldering is something that requires much more experience and hand-eye precision than welding lithium cells.

Spot Welding Vs Soldering: Conductivity And Resistance

When reading online discussions about soldering vs spot welding lithium cells, it's common to come across arguments on both sides in regard to which one makes a better electrical connection. While it's true that a poor solder connection can be electrically much worse than a spot-welded connection, that is only true if it's a poor solder connection.

Because of the difference in surface area between the two, a well-soldered copper wire will be an electrically superior connection to a spot-welded nickel strip. This is because copper can carry about 4x the amount of current making it one of the best metals to use for joining cells in battery packs.

The problem is that in order to get that superior connection, a large amount of heat is introduced into the cell from the soldering process. Another thing to consider is that the electrical connection provided by spot welding nickel strips is more than enough as long as, like soldering, that process is done well.

So, if laying on the nickel in a certain way and using a certain number of nickel layers when spot welding can achieve sufficient current carrying characteristics, then the superior ampacity of soldered wire no longer becomes an advantage. This makes it so you are left with only added heat of the soldering process and none of the benefits.

Comparing Spot Welding Vs Soldering: Strength

When comparing traditional welding to soldering, welding is always superior. Welding actually melts all of the materials and forms a strong, solid bond while soldering joins the materials through other means, and only the solder melts.

This, however, is not the case when it comes to soldering vs spot welding. Spot welding is just that, a spot. A spot weld has a tiny, tiny surface area. Most of the current is not flowing through the spot weld, but rather through the nickel being pressed flat down onto the cell by the spot weld.

In comparison, a solder joint is an extremely large connection that has a huge surface area and it itself can carry a high amount of current. The problem, however, is that a battery simply doesn’t need to have electrical connections that are that robust and physically strong. In fact, the large nature of a solder connection is more of a burden than a feature.

So, again, when it comes to solder vs spot welding lithium cells, you are left with only the added heat of the soldering process while the additional benefits are negligible or in some cases a nuisance.

Reliability of a Spot Welded Cell vs Soldered One

Soldering vs spot welding is about the same in this regard. If you do a good spot weld, it's not going anywhere. It’s the same with soldering. As long as you don’t use some sort of pipe flux that has an acid in it that corrodes connections later (that is more common than you may think) the solder connection is not going to fail under normal operating conditions.

The problem, however, is one of scale. A larger battery needs more cells. More cells require more solder joints. More solder joints require more heat and provide more room for error. Other than the heat, the same is true for welding lithium cells, but it's a lot easier to make consistent connections with a welder compared to soldering.

Ease of Construction

As mentioned above, a larger battery made from the same cells logically requires more cells. If your battery requires 100 cells, that’s 100 solder connections per side that you have to make. Making 200 advanced, high-temperature solder joints is very hard and takes a long time. So, while it may be trivial to solder a 4 or even a 40-cell pack, things can get out of hand really quickly and can turn a battery build that would have taken a week with a spot welding into a month-long process with a soldering iron.

The worst part is that even after spending all that additional time soldering a lithium-ion battery, you are left with an inferior battery. This is because no matter what you do, the heat produced by the soldering process will always reduce the capacity of each cell you solder.

Repairability

Some battery packs over time will have issues that cause them to break. Being able to repair a broken battery can save you some money over buying a new pack. So taking repairability into consideration can be an important factor to consider.

Both spot welding and soldering lithium cells suffer in regard to repairability. This is because both the spot welding and soldering processes are inherently permanent and offer no built-in way of being reversed. Spot welding cells has the advantage that in order to remove a welded connection, your only option is to tear it off. In contrast, a soldered connection can always be desoldered.

The problem, yet again, is that the desoldering process puts as much heat as (and often much more) than the heat required to solder them, further damaging the cells. In the case of welded connections that have to be torn off, it's almost impossible to get the cell perfectly flat again. This makes it so that the next welded connection won't be nearly as electrically strong as it could have been. So, neither spot-welded nor soldered lithium cells are good for repairability.

Conclusion

Those that are new to building batteries may be wondering which way to go, soldering vs spot welding lithium cells. Well, the answer is clear.

It's always better to spot-weld lithium cells vs soldering them. Spot welding is easier to learn because the type of soldering required to solder battery cells is advanced. If done really well, a soldered connection can be electrically stronger than a welded connection, but it comes at the cost of lost capacity.

A spot-welded connection is much smaller than a soldered connection. It’s also important to consider that a spot weld is something that essentially happens on a 2d plane. A solder joint, on the other hand, is a large structure that extends off the surface of the plane it is being soldered to. This makes a soldered connection physically stronger, but again, this extra strength is not needed and comes at the cost of several other key performance metrics. Welded connections are plenty robust enough for building battery packs and their nature makes them ideal for compact battery construction.

When comparing soldering vs spot welding lithium cells, both connection types are equally as reliable if done properly, but it's a key consideration that the soldering process itself does things to the cells that makes them less reliable. A soldered lithium battery is much, much more difficult to build than a welded battery, but they are both equally as difficult to repair. This makes sense because both welding and soldering are inherently permanent processes.

We hope this article helped you learn everything you needed to know about soldering vs spot welding lithium cells. Thanks for reading!