Which Metal To Use For Building Battery Packs

Table of Contents

- Why Is Copper Used In Batteries?

- Why Is Nickel Used To Build Batteries?

- Why Is Nickel Required To Build A Copper Battery?

- Can Copper Be Spot Welded?

- Is A Copper Battery Always Better Than A Nickel Battery?

- Pros & Cons For A Copper Battery:

- Pros & Cons For A Nickel Battery:

- What About Nickel Plated Steel for Batteries?

Some of the shiniest and nicest looking battery build pictures are pictures of batteries built with copper. This is in contrast with most ‘regular’ batteries that you see shared on social media that use nickel instead of copper. If you are interested in getting into battery building, you may be wondering which metal to use for building battery packs.

If you are building a small, low-current battery pack or a large, medium-current battery pack, nickel is the best metal to use. If, however, you are building a compact, high-current battery pack, copper is going to be the best material to use. If you have a welder that is more toward the lower end, you will need to pick up some nickel-plated steel to use for copper-nickel sandwiches. This will give you much better welds, but if you have a kWeld, you can get away with using pure nickel.

While it may seem and certainly looks like copper is the best metal to use for building battery packs, this is not always the case. In this article, we will discuss which metal to use for building battery packs. We will also explain why each metal is used, and what their drawbacks and advantages are.

Why Is Copper Used In Batteries?

Copper is used for building battery packs because it is both highly electrically conductive and highly thermally conductive. Copper is an effective means of both transferring power from one cell group to another and wicking away heat generated within the core of the cells.

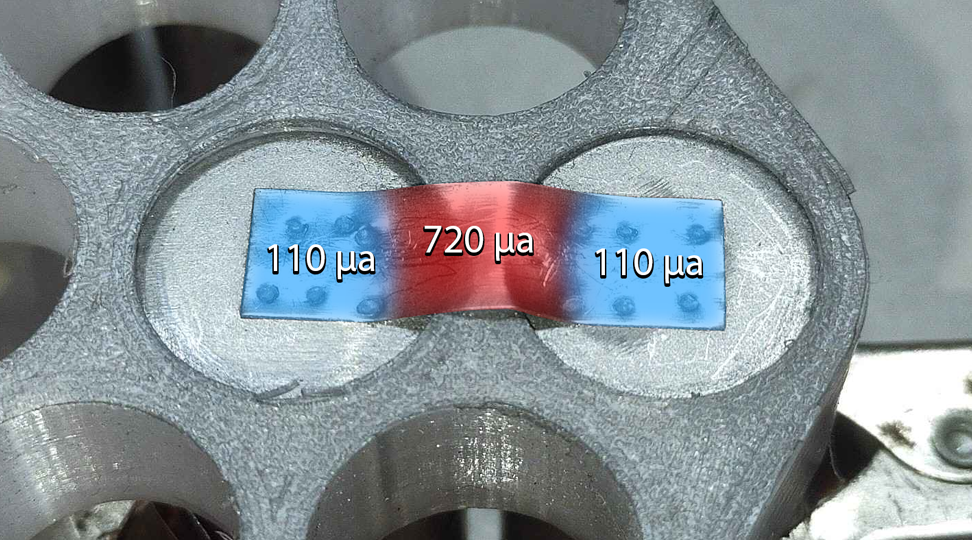

Copper has around 5 times less resistance than nickel. This means that copper is about 5 times more conductive than nickel. This aspect alone makes it clear why copper is a desirable metal to use for building battery packs.

Due to copper having a lower resistance than nickel, you can carry about 5 times the current with the same amount of material.

Why Is Nickel Used To Build Batteries?

Nickel is used to build battery packs because it's both low cost and has excellent anti-corrosion properties. Nickel is easy to work with because it has 5 times more resistance than copper. This means that nickel is about 5 times easier to spot weld than copper. For this reason, even when building a copper battery, nickel is required.

Why Is Nickel Required To Build A Copper Battery?

This is because common spot welders are simply not powerful enough to directly weld copper. So, a little nickel is needed to form a high resistance junction to indirectly weld the copper.

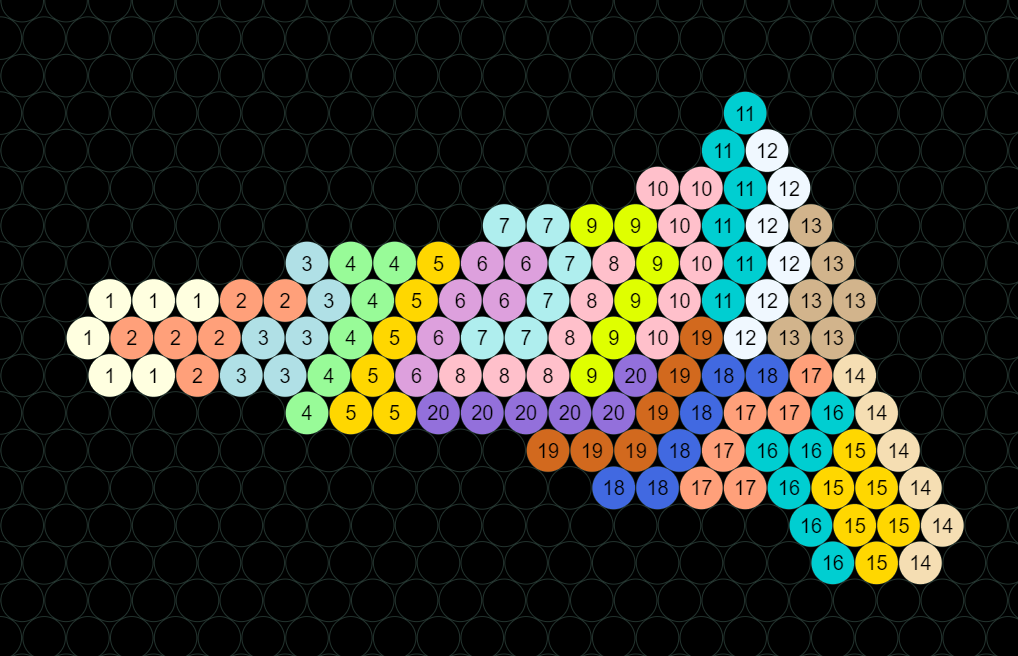

In a pure nickel battery, many layers of nickel are needed to be able to support the same amount of current as a single layer of copper. This may sound like a major pain, but it's really not. In fact, the first layer of welds are the only ones that have a normal level of welding difficulty. Each subsequent layer is easier and easier to weld, and in many cases, layering nickel can achieve the same exact electrical characteristics as copper.

Can Copper Be Spot Welded?

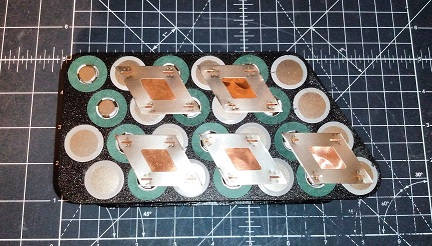

Not directly. At least not with the commercially available spot welding machine within reach of the average person. The copper-nickel sandwich was invented to get around this fact. Using a copper-nickel sandwich, a decently powerful spot welder can weld copper. We have an article outlining what spot welders are the best for spot-welding copper/nickel.

There are these massive, expensive, super complicated machines that can weld copper directly. The problem is that these machines are huge, industrial machines that are far outside of the scope of DIY and even most small businesses.

Is A Copper Battery Always Better Than A Nickel Battery?

No. A copper battery is only better than a nickel battery if the batteries are completely identical and the same amount of material is being used. The thing is, when you build a copper battery, you have to use a lot less material.

If you tried to build the same battery using the same cells and amount of material being used and exchanged the copper for nickel, then sure, the copper battery would be way better.

If you built the same battery and used enough nickel to compensate for the fact that nickel is much less conductive than copper, then the batteries will have the same exact level of performance.

A nickel battery can be just as good as a copper battery, it just takes a lot more layers of nickel and a lot wider sections of nickel strip. The problem is that some batteries need to be so compact, that there is simply not enough space between the cells and simply not enough cells, in general, to be able to push around big currents without copper.

If you have enough space, time, and materials, then a nickel battery really can be just as good or even better than a copper battery. Again, there are just some fringe cases where the battery layout is such that the only way to achieve high currents is to use copper. Those situations, however, are pretty rare.

Pros & Cons For A Copper Battery:

Pros:

- Uses less material

- Looks nicer

- Bragging rights

Cons:

- Requires advanced welder

- Requires more time and patience

- More expensive in terms of both labor and materials

- Copper corrodes rather rapidly (but this can be prevented with something as simple as tape)

Pros & Cons For A Nickel Battery:

Pros:

- Uses more material

- Requires only medium-power welder

- Requires less welding skill

Cons:

- Requires several layers for the same current carrying capacity as copper

What About Nickel Plated Steel for Batteries?

Nickel-plated steel is basically just steel with an extremely thin coating of nickel. The coating of nickel is only to prevent corrosion, so that means all of the power flows through the steel. Steel is an extremely poor electrical conductor and nickel-plated steel should never be used to directly build a battery.

For a general comparison, copper is 14 times more conductive than steel and pure nickel is 3.5 times more conductive than steel. To put it simply if you had a strip of copper that was 1mm wide and .1mm thick you would need in the same thickness a 4mm wide strip of pure nickel and a 14mm wide strip of steel!

It has even worse resistance characteristics than pure nickel, nickel-plated steel is an even better metal to use for building copper battery packs. While it's true that a copper battery can be welded with pure nickel squares, it's much easier on the welder and much easier to get a good weld if you use nickel-plated steel.

Conclusion

Just because a battery is not made with copper does not mean that it's a low-quality, low-current battery. Like most other things, which metal to use for building battery packs comes down to your specific use case and preferences.

For building a smaller, lower-power battery pack, copper is completely unnecessary and only serves to make the battery look nicer. Even if you are building a large, medium-to-high current battery pack, nickel will do just fine as long as you take care with making good, consistent connections that are layered enough. If, on the other hand, you are building a tiny battery that has to be able to support big currents, copper is going to be the best metal for your build. It takes a more powerful welder to weld copper nickel sandwiches. It also takes more time and skill, so if you can avoid it, you should. If you do find yourself going down that route, make sure to pick up some nickel-plated steel as that makes copper welding with commercially available spot welders much easier.

We hope this article got you up-to-date on which metal to use for building battery packs. Thanks for reading!