Pulse Arc vs. Resistive Spot Welding: Do You Actually Need the Upgrade?

Table of Contents

Introduction

If you're on this website reading articles about batteries, then you probably are already very familiar with the concept of spot welding. But, if like me, you are probably not super familiar with the concept of pulse arc welding. This is a somewhat new type of welding, in the context of battery building at least. And, it's been talked about in the community, rather recently, in various different places. So, I just wanted to address some things about pulse arc battery welding.

Resistive Spot Welding

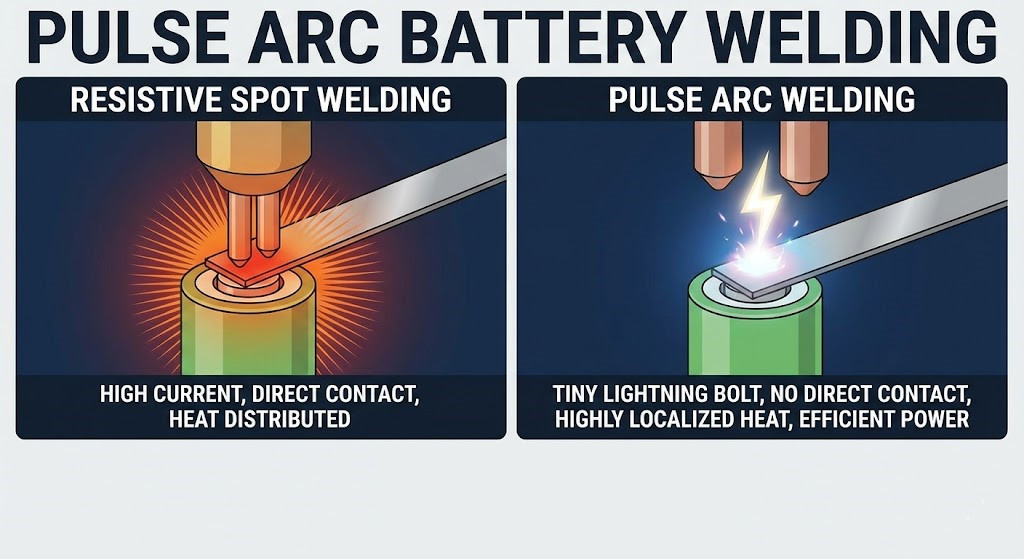

First we have to cover the traditional welding basics. Usually when someone mentions spot welding or battery welding, they're talking about resistive spot welders. Resistive spot welders, like a K-Weld, AWithZ, or glitter welders, form a weld by passing a massive amount of current into the work material. This welding process depends on the contact point of the welds being the highest resistance points in the welding circuit. This makes those points also the points where most of the heat energy is lost to.

This process creates a highly localized, extremely hot area that liquefies any metal near it, forming a strong, clean, fast bond.

Pulse Arc Battery Welding

Pulse arc welding, on the other hand, is a totally different situation. Pulse arc battery welding is similar to firing a tiny lightning bolt at the work material, which in this case is a battery cell.

You don't make direct contact with it. Instead, like other welders, you bring the electrode very close, and when you apply the weld, it sends current into the electrodes that forms an arc. This arc is essentially a very tiny, very hot lightning bolt for a tiny amount of time.

Power, Control, and Requirements

As you would expect from the description, pulse arc battery welding is much more powerful than resistive welding, but is much less repeatable and much harder to perform overall. I'm not saying that it can't be learned well. Any form of craft like this can be learned well. And as we see with experienced TIG and MIG welders, it can be done very well while rendering extremely professional results.

This does not change the fact that due to the type of welding it is, it requires a much higher degree of skill and control to properly and effectively operate compared to other forms of battery welding.

What Are The Benefits Of Pulse Arc Battery Welding

Power delivery in pulse arc battery welding is significantly more efficient than in traditional resistive spot welding. This efficiency allows a smaller, lower-cost machine to produce welds on similar material thicknesses that would otherwise require a much larger and more expensive resistive spot welder.

The reason lies in how energy is delivered.

In a resistive spot welder, a large current is driven through an entire electrical circuit that includes the power supply, cables, electrodes, and the workpiece itself. For example, a welder operating at 2,500 amps and 9 volts may appear to deliver over 22 kilowatts of power. However, that power is not applied solely at the weld junction. Instead, it is distributed throughout the entire circuit, resulting in significant energy loss as heat in cables, electrodes, transformers, MOSFETs, and capacitors. Only a small portion of the total energy actually contributes to heating the weld interface.

Pulse arc battery welding works differently. Energy is stored and then released in a very short, high-current pulse that creates a localized arc or plasma at the electrode-to-cell interface. While the process still relies on a complete electrical circuit, the current density and heating are concentrated at the surface where the weld is formed. The bulk material carries comparatively little heat, and losses in cables and internal components are greatly reduced due to the extremely short pulse duration.

Sp, pulse arc welders can achieve strong, consistent welds with lower overall energy consumption, reduced thermal stress on components, and significantly smaller equipment.

But Is A Pulse Arc Battery Welder Worth It?

Probably not because the only reason you think you need it is so you can weld materials that are far thicker than you actually need. It's extremely common to overbuild and overengineer the series conductors simply based on the concept of overbuilding to underworry or overpromising to overdeliver.

Everyone likes to err to the side of caution, and I fully understand that. But chances are you probably don't need as thick of a series conductor as you may think. If you do, it's probably a lot easier to just buy a slightly more expensive resistive spot welder, or better yet, just add a few more layers with the welder you already own.

Ultimately, I'm still on the fence about these welders. I have never used one and I don’t know anyone else that has used them either.