Do You Need a Special Charger For a Lithium Battery?

Table of Contents

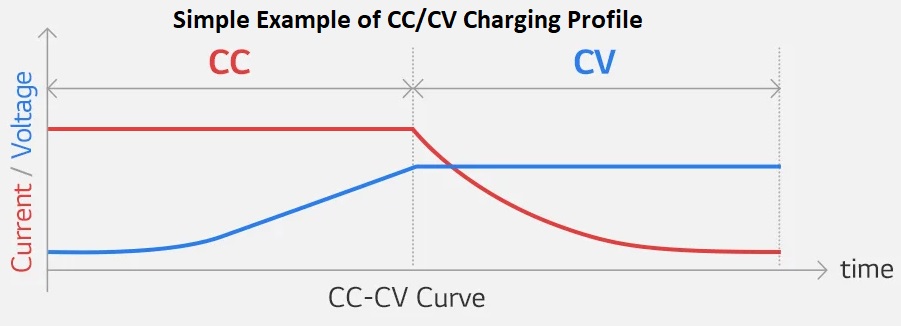

A special charger is essential for charging a lithium battery due to the specific requirements of lithium-ion cells. Lithium ion battery cells must be charged using a method that has 2 phases. Constant Current (CC) and Constant Voltage (CV). In the CC phase, the charger supplies a steady current, letting the voltage go to whatever it needs to be to maintain that current. Once the battery reaches a certain voltage threshold, the charging process shifts to the CV phase, which maintains a constant voltage while letting the current naturally fall to zero as the charge finishes. This special charging method is required to prevent overcharging, which could lead to electrolyte breakdown, increased internal pressure, or even thermal runaway.

Using a charger not specifically designed for lithium batteries, such as a standard lead-acid charger, can result in too much current being delivered too quickly, risking overheating and damage to the lithium cells. A special charger that adjusts voltage and current during different charging stages is needed for lithium batteries

What Do I Need to Charge A Lithium Battery

To effectively charge a lithium-ion battery, it is essential to use a charging method that employs both Constant Current (CC) and Constant Voltage (CV) phases. This approach is important due to the unique electrical characteristics and requirements of lithium-ion cells. Understanding the charging profile of lithium batteries will allow you to comprehend how charging works and enable projects like building your own lithium battery charger.

Constant Current (CC) Charging Phase:

In the initial phase of charging, a Constant Current mode is utilized. This phase ensures a controlled and steady flow of current to the battery. The importance of this lies in the battery's low internal resistance, which, if not managed correctly, could lead to rapid and excessive current flow. This unregulated current can cause overheating, stress, and potential damage to the battery cells, compromising performance and decreasing lifespan.

In the CC phase, the charger supplies a steady and controlled current to the lithium battery. The key here is the word 'constant' – the current does not fluctuate. This consistency is super important because it allows the battery to be charged in a safe and efficient manner, especially during the initial stages when the battery's voltage is below its set maximum level. By maintaining a uniform flow of energy, the CC phase ensures the battery cells receive an even and stable charge, preventing stress and potential damage.=

Constant Voltage (CV) Charging Phase:

As the battery reaches a certain voltage threshold, the charging process transitions to the Constant Voltage phase. This stage is critical to maintain the voltage at a stable, predetermined level, effectively preventing overcharging. Overcharging a lithium-ion battery can be particularly detrimental, leading to issues such as electrolyte breakdown, increased internal pressure, and in extreme cases, thermal runaway and cell rupture.

The need for a CC/CV charging method is not just a safety measure; it also ensures optimal charging efficiency and longevity of the battery. Properly charging a lithium-ion battery using a CC/CV method maximizes the battery's capacity, health, and cycle life, ensuring reliable performance over an extended period.

Once the battery's voltage reaches a certain level (near its maximum), the charger switches gears from focusing on current to prioritizing voltage. In this phase, the charger maintains a constant voltage. The trick here is that as the battery gets closer to being fully charged, the current naturally tapers off. The CV phase is like a fine-tuning process; it takes over to top off the battery charge in a way that maximizes capacity without crossing into the danger zone of overcharging.

Basically, the CC phase is all about providing a steady stream of energy, while the CV phase is about fine-tuning that energy delivery to reach full charge safely and efficiently. Both phases work together to ensure a lithium-ion battery charges up just right - full of energy and ready to go but without any of the risks that come from overcharging or uneven charging.

Choosing the Right Charger Voltage and Current

Lead-acid chargers are designed for robust, less sensitive batteries and often lack the precision needed for lithium-ion batteries. They can provide too much current too quickly, not adjusting to the battery's charging stages. This mismatch can lead to overheating or damage since lithium-ion batteries require specific charging patterns with controlled voltage and current adjustments. In simple terms, it's essential to use a charger that's tailored for the specific needs of your lithium-ion battery to ensure safety and longevity.

How To Find Out Charge Current

The C rating is a measure of the rate at which a battery can be charged or discharged relative to its maximum capacity. To figure out the maximum safe charging current for your battery, you need to know both its capacity (in amp-hours, Ah) and its C rating. The formula is pretty straightforward: just multiply the capacity of the battery (in Ah) by the C rating. For example, if you have a lithium-ion battery with a capacity of 2 Ah (2000 mAh) and a C rating of 1C, you can safely charge it at a maximum rate of 2 amps (2 Ah x 1C = 2 A).

But let's say you have a higher C rating, like 2C. This means you can charge the battery twice as fast, so for our 2 Ah battery, you could safely charge at 4 amps (2 Ah x 2C = 4 A). Don’t go over this calculated charging rate, as doing so can seriously shorten the battery's life or even pose safety risks like overheating.

If you are unable to find the C rating of the battery pack, you can also use .25C this is a safe level for the charging of most battery packs and cells.

How to Determine the Charge Voltage for Lithium-Ion Batteries

Finding the correct charge voltage for a lithium-ion battery is crucial for its longevity and performance. Here's a step-by-step guide to help you determine the appropriate charge voltage:

- Identify the Battery Type: Different types of lithium-ion batteries have unique voltage requirements. Common types include:

- Lithium Cobalt Oxide (LiCoO2): Often used in phones and laptops, with a full charge voltage of about 4.2 volts per cell.

- Lithium Iron Phosphate (LiFePO4 or LFP): Known for safety and stability.

- Lithium Manganese Oxide (LiMn2O4): Common in power tools and medical devices.

- Check the Number of Cells: The charge voltage depends on the number of cells connected in series (S) in your battery pack.

- For a single-cell battery, the charge voltage is the same as the cell's full charge voltage.

- For multi-cell packs, multiply the single-cell full charge voltage by the number of cells. For example, a 3S pack of Lithium Cobalt Oxide batteries would have a charge voltage of 12.6 volts (4.2V x 3).

- Refer to the Battery Label: The battery pack label often indicates the charge voltage along with the maximum charge amperage. This information can help ensure you're charging the battery correctly.

Charger's Role in Battery Longevity

The charger you use with a lithium-ion battery isn't just a tool to recharge it. It plays a crucial role in the battery's overall health and longevity. The charging speed, for instance, is a key factor. Quick charging might seem convenient, but it's not always the best for your battery's lifespan. Fast charging can lead to increased heat and stress within the battery, which over time, can degrade its components faster than usual.

Charging a battery to a voltage below its maximum charge voltage can be beneficial for its lifespan. This practice, known as partial charging, reduces stress and heat generation within the battery, thereby slowing down the degradation process. This is particularly relevant for lithium-ion batteries, where keeping the charge between 20% and 80% of the total capacity can significantly extend their cycle life.

Each lithium-ion battery is designed to be charged up to a specific voltage. Using a charger that exceeds this voltage can overcharge the battery, leading to damage or even safety hazards like overheating or swelling. An appropriate charger will also ensure that the battery doesn't discharge too deeply, as deep discharges can also harm the battery's long-term health.

Understanding Nominal Voltage

Nominal voltage is a term that often pops up when discussing batteries, especially lithium-ion types. It's like an average measure of the battery's voltage during its discharge cycle. The voltage of a battery isn't static; it fluctuates. For example, when a lithium-ion battery is fully charged, it starts at a higher voltage which gradually decreases as the battery discharges. This is referred to as the voltage range of the cell or of the battery as a whole.

In practical terms, if you're working with a 12-volt system, it doesn't mean the battery always outputs exactly 12 volts. For a lithium-ion battery, achieving a 12-volt nominal output typically involves configuring three cells in series, referred to as a 3S setup. NMC (Nickel Manganese Cobalt Oxide) is a common chemistry used in these setups. However, because of its discharge voltage range, a 3S NMC battery might not always efficiently run equipment that requires a stable 12-volt supply. This is because the voltage can drop below the required level for most 12-volt equipment as the battery discharges.

Conclusion

A special charger is indeed necessary for lithium batteries due to their unique charging requirements. Lithium-ion batteries must be charged using a method that involves both Constant Current (CC) and Constant Voltage (CV) phases. This two-phase approach ensures that the battery is charged safely and efficiently. During the CC phase, the charger provides a steady current, which is crucial for managing the battery's low internal resistance and preventing rapid, excessive current flow that could lead to overheating or damage. As the battery reaches its voltage threshold, the process shifts to the CV phase, where the charger maintains a constant voltage while the current gradually decreases to zero. This method prevents overcharging, which can cause electrolyte breakdown, increased internal pressure, or thermal runaway, posing serious safety risks.

Using a charger not specifically designed for lithium batteries, such as a standard lead-acid charger, can result in delivering too much current too quickly, leading to overheating and potential damage to the battery cells. Lead-acid chargers lack the precision needed for the controlled voltage and current adjustments required by lithium-ion batteries. Therefore, to ensure safety, efficiency, and longevity of lithium batteries, a charger tailored to their specific needs is essential. Such chargers incorporate the CC/CV method, which maximizes the battery's capacity, health, and cycle life, ensuring reliable performance over time while mitigating the risks associated with improper charging.